Nailor Industries Inc. reserves the right to change any information concerning product or specification without notice or obligation.

Page 2.094

3/16 IOM-MBFDIMP

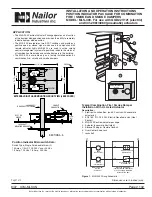

OPERATION AND MAINTENANCE PROCEDURES

MULTI-BLADE AND TRUE ROUND FIRE DAMPERS

MODEL SERIES: (D)1200(SS)(-3)(-OW)(-DOW), D1250

AND 1290F(-SS)

Dampers are an essential part of the fire protection system

in a building. The NFPA recommends that fire dampers be

tested periodically to verify the operational abilities of each

installed damper. See NFPA 80,

Standard for Fire Doors

and Other Opening Protectives

, for Operational and

Periodic Inspection and Testing details.

CAUTION:

High torque helical spring under tension, ensure HVAC

fans are turned off. Testing spring assisted fire dampers

under airflow conditions is

NOT RECOMMENDED

and

may severely damage or destroy ductwork. Use protective

eyewear or safety glasses. Keep hands out of the blade

path, as this can cause serious injury. Keep any hard

objects or tools out of the blade path as they can damage

the blades when closing.

Releasing of the fusible link

1. Using a suitable heat source, apply heat at a slightly

higher temperature than the rating of the fusible link until

the link melts. When applying the heat to the fusible link

position the heat source in a manner so no heat is directed

towards the spring as the excessive heat can negatively

affect the spring performance.

AS SOON AS THE LINK HAS MELTED, THE

SPRING WILL FORCE THE BLADES TO CLOSE

INSTANTANEOUSLY. THE BLADE PATH MUST BE

KEPT CLEAR.

Reloading the spring assembly

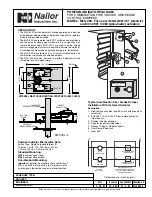

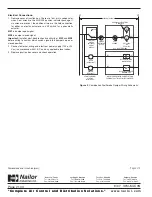

2. Loosen the jackshaft from the bolt on crank arm

quadrant, located on the jackshaft side opposite of the

spring assembly

(A)

. Do not remove the bolt completely.

See Detail 1.

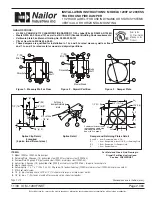

3. Attach a pair of vise grips on the jackshaft

(B)

and turn

upwards until the two pins on the spring assembly are at a

distance at which the new fusible link can be installed

(C)

.

This is approximately 90° of rotation. See Detail 2.

Note:

On smaller size dampers, two vise grips may be

required to open the damper. Use one vice grip to open as

much as the duct free area will allow, then set the second

vise grips on the jackshaft per above. Unlock the first set of

vise grips, remove and turn the second set upwards as

free area will allow. Repeat as necessary.

4. Place the new fusible link over the two pins on the

spring assembly (making sure temperature rating is visible)

and locate in the pin grooves

(C)

. See Detail 2.

Required Items:

(1) Protective eyewear or safety glasses

(1) Pair of work gloves

(1) Suitable heat source

(2) Vise grips

(1) 1/2" (13) wrench

(1) Needle nose pliers

(1) Replacement "Globe" Fusible link per damper section,

of the same temperature rating as the original link.

Detail 1

Detail 2

Page 1 of 2