14

shape of the cutting work piece. (apply the leading trail if it is for beeline cutting: apply the radial pole if it is

for round cutting or round pilot)

*

Pull out the connector of the torch and change with the remote control plug (optional)

*

Adjust suitable speed according to the thickness of the work piece, and adjust the inverse ordinal switch to the

cutting direction

*

Turn on the remote control to establish the plasma pilot, after cutting through the working piece, turn on the

power supply of semi-automatic cutter to start cutting, keep an eye on the cutting slot to adjust a suitable

cutting speed during the cutting phase.

*

Turn off the remote control switch when cutting ends, and then withdraw the torch and the cutting ends.

Manual Round Cutting

*

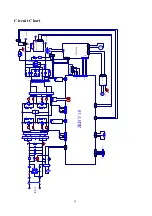

Install the torch according to the following sketch and adjust the length of the rail as per the radii of work piece.

*

Manual round cutting or round pilot cutting according to different cutting type.

Notice while cutting

*

If unnecessary, please do not ignite the leading pilot in the air, or it will reduce life-span of the torch’s electrode

and puzzle.

*

It will be better to start cutting at the edge of the work piece, unless you must do perforation operation on the

work piece.

*

Be sure that the splash is spilt from the bottom of the work piece. If it is spilt from the top of the work piece,

then you must move the torch too quickly, or the thickness you chose could not cut through the work piece.

*

Keep certain space between the nozzle and the work space. If press the torch onto the work piece heavily, it will

make the nozzle stick onto the work piece, thus it can not move smoothly to cut.

*

Templet or accessorial equipment is required to cut round work piece and edge inosculation work piece.

*

It is easier to “pull” than “push” during the cutting process

*

Keep the torch’s nozzle vertical against the work piece, and observe if the pilot is moving along the cutting line.

*

While cutting the thin work piece, the thin mode can get best cutting quality with low wastage and longer life

span of electrode and nozzle.

*

Do not repeat to press the torch switch rapidly, otherwise the pilot system and relative work piece will be

destroyed.

*

The

Non-HF Arc-pilot Series

cutter’s working range is 0.4~0.45MPa.

HF Arc-pilot Series

cutter’s working

range is0.4

~

0.55MPa.

Safety Requirement

*

Never allow the electrophorus torch to aim at any part of the body.

*

Make sure to wear protection glasses and protection glove while operating.

*

Make sure to work in places where there are exhaust or ventilation facilities to keep fumes or emissions away