VJ-1304 INSTALLATION MANUAL

VJ1304E-I-00

6

1

2

2

1

2

1

2

1

2

2

1

1

2

2

1

1

2

1

2

3

4

4

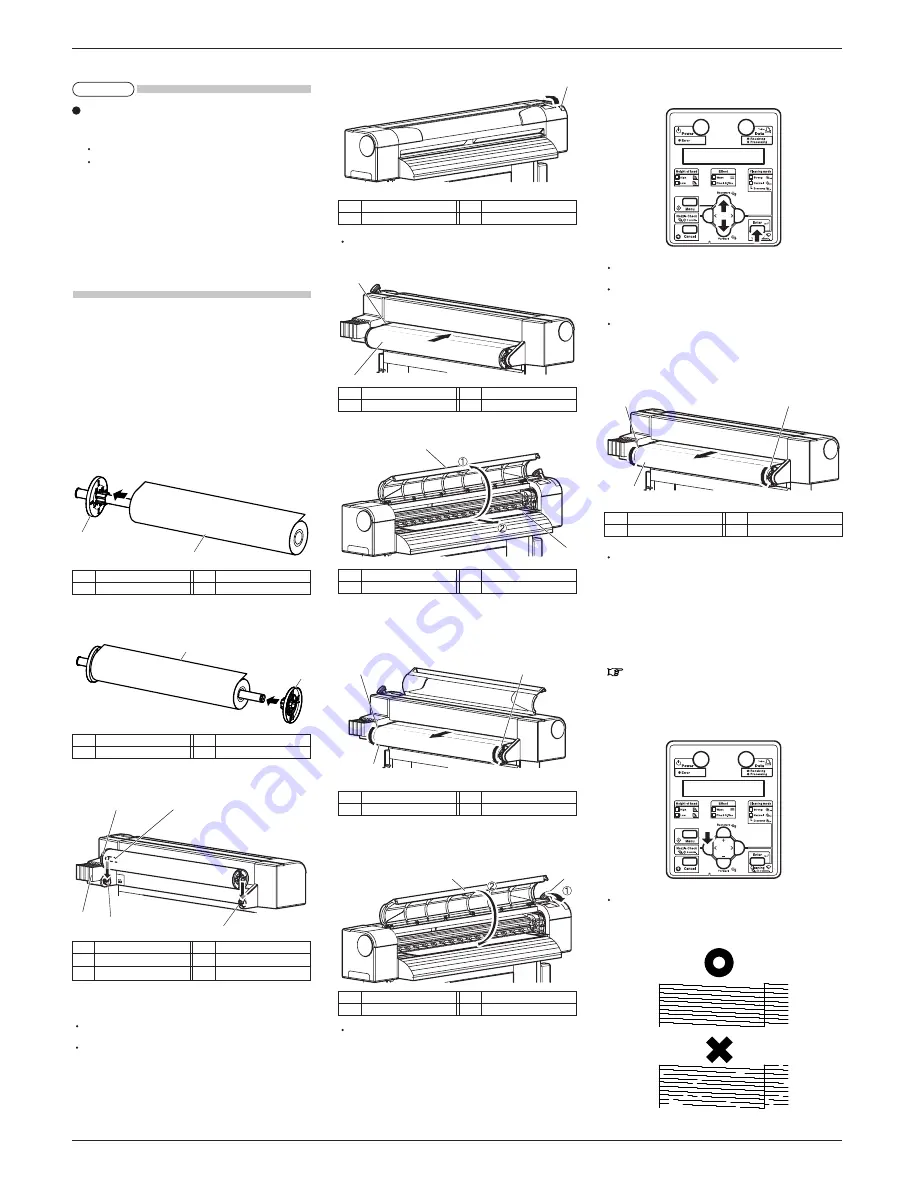

6. Push the media loading lever backward.

The operation panel displays "Lever Up".

7. Feed the roll media into the media feed slot.

8. Open the front cover, and pull out the roll media.

9. Press and hold the front edge of the roll media and

wind it back with the scroller to remove a media

bend or slant.

10. Return the media loading lever to the front and

close the front cover.

The operation panel displays the media type setup

menu.

11. Press the [+] key or [-] key on the operation panel to

select the type of the loaded media and press the [En-

ter] key.

This confirms the media type.

The operation panel displays "Media Initial", and

media initial operation starts.

After the media initial operation is completed, the

operation panel displays "Ready to Print", and the

display enters normal status.

12. Wind back the roll media with the scroller to remove

a media bend.

The media loading is complete.

9 Checking printing conditions

Check the condition of the print head after the ink re-

plenishment.

1. Turn ON the printer and load the roll media.

8 Loading the roll media

2. Confirm that the printer functions normally.

3. Press the [<] key on the operation panel for two

seconds or more.

Nozzle check printing starts.

4. Check the sample print for blurred or missing

parts in the check pattern.

(Continue to next)

(Cont'd)

If the Nozzle check printing is performed immediately

after the ink replenishment is complete, the following

results may occur.

Printed line becomes blurred.

The data is partially not printed.

In such cases, follow the Operation Manual "6.2.3

Head cleaning" and charge a small amount of ink.

Then, check the printing result.

If there is no improvement in the print result even

after refilling a small amount of ink, leave the printer

for one hour or more, and refill a small amount of

ink again.

If there is still no improvement, contact MUTOH

local dealer.

8 Loading roll media

This section explains how to load roll media.

Follow the steps below to load roll media.

1. Set roll media in the scroller so that the roll media

gets winded up in the direction of anti-clockwise

when viewed from the fixed flange side.

2. Push the roll media until its core hits the right

edge of the fixed flange.

3. Attach the movable flange so that it is firmly at-

tached to the roll media core.

4. Set the scroller onto the scroll receiver with the

fixed flange side facing the ink cartridge slots.

5. Turn ON the product.

The product starts the initial operation.

The operation panel displays "Media End".

No.

Name

1

Media loading lever

No.

Name

1

Roll media

No.

Name

2

Media feed slot

No.

Name

1

Front cover

No.

Name

2

Roll media

No.

Name

1

Media loading lever

No.

Name

2

Front cover

No.

Name

1

Roll media

No.

Name

2

Scroller

No.

Name

1

Roll media

No.

Name

2

Scroller

No.

Name

1

Fixed flange

No.

Name

2

Roll media

No.

Name

1

Movable flange

No.

Name

2

Roll media

No.

Name

1

Scroller

2

Fixed flange

No.

Name

3

Ink cartridge slot

4

Scroller receiver

NOTE