1. ADJUSTMENTS:

3. WATER DRIPS OR WILL NOT SHUT OFF:

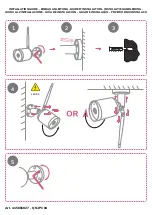

a. Cartridge – The water flow can be adjusted using a slotted narrow blade screwdriver and turning

clockwise to increase flow and counterclockwise to decrease flow.

b. Verify minimum 20 psig supply line flow pressure.

a. Open fixture. Loosen nuts holding valve bracket assembly to bottom of fixture but, do not remove. Move

complete valve bracket assembly further back from the front push pad and tighten to lock in place.

b. Replace valve cartridge.

a. Ensure water supply service stop valve is fully open.

d. Check the water inlet “Y” strainer. Sediment from the main supply can get trapped in the screen along

with installation materials such as pipe dope and flux. The screen should be cleaned and checked on a

regular basis and replace if needed.

e. The cartridge valve located in the water control assembly or bubbler can also become clogged with

foreign material. The cartridge valve can only be replaced and not repaired.

TROUBLE SHOOTING:

f. Check flow adjustment. See start up note #3.

2. RESTRICTED OR NO WATER FLOW:

g. Flow control in solenoid valve outlet elbow clogged remove & clean.

c. Bubbler Stream - Bubbler can be rotated slightly to direct the stream backwards or forwards. Adjust the

stream to minimize splashing. Splashing may occur from bubbler stream if the unit is not level. Shim lower

mounting point, if necessary, to level chiller.

b. Cold Water Thermostat – The water temperature can be adjusted using a slotted screwdriver and turning

clockwise to make colder and counterclockwise to make warmer.

c. Check for twists or kinks in outlet tubing.

h. No power to transformer connections, loose or wires cut.

A152-VR

Page 9 of 11

Date:

10/29/2020

7021-022-001

MURDOCK MFG. •

15125 Proctor Avenue • City of Industry, CA 91746 USA

Phone 800-453-7465 or 626-333-2543 • Fax 626-855-4860 • www.murdockmfg.com

Member of

2. If there are stubborn spots or if you wish to treat a scratch, synthetic abrasive general purpose pads such as

scotch brite are recommended.

3. Stainless steel should be kept clean at all times. If a coating of stainless steel cleaner/polish is maintained,

stainless steel surfaces will retain their new, clean, polished appearance indefinitely.

3.

Periodically remove fountain top and clean out in-line strainer.

4.

Periodically remove access panel of cooler and clean out inline “Y’’ strainer

For Stainless steel units:

For Powder coated units:

Units should be cleaned using a mild soap solution with a sponge or cotton cloth.

Wipe down surfaces then rinse with clean water.

2.

Excess dirt or poor ventilation will cause the compressor overload protector to turn the compressor off and it

will cycle on and off with no cold water coming out of bubbler. Periodically clean with vacuum cleaner, air

hose or brush the condenser fins and cabinet ventilation louvers. In environments where dirt and dust is

more prevalent, clean more frequently.

1.

Motors have lifetime lubrication and do not require scheduled maintenance.

CLEANING & MAINTENANCE GUIDE:

1. To Remove water spots or rust spots, stainless steel cleaner/polish on a cloth is recommended.

CONTEMPORARY WATER COOLERS

I N S TA L L AT I O N / M A I N T E N A N C E I N S T R U C T I O N S

DRINKING FOUNTAINS