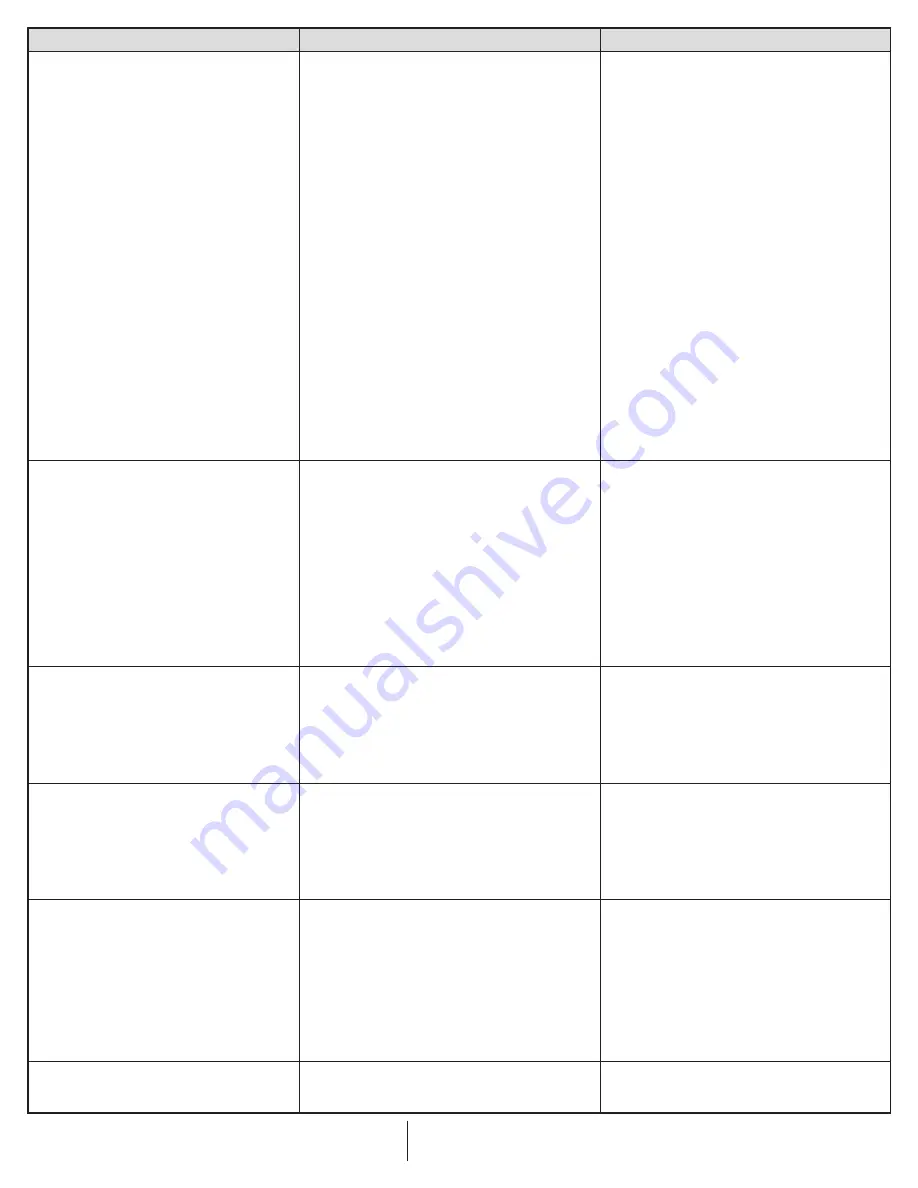

SYMPTOM

POSSIBLE CAUSE(S)

CORRECTIVE ACTION

Little or no discharge

1. Casing not initially filled with water to prime pump

2. Total head too high

3. Suction lift too high, or too long

4. Impeller plugged

5. Hole or air leak in suction line

6. Foot valve too small

7. Impeller damaged

8. Foot valve or suction line not submerged deep

enough in water

9. Insufficient inlet pressure or suction head

10. Suction piping too small

11. Motor wired incorrectly

12. Casing gasket leaking

13. Suction or discharge line valves closed

1. Fill pump casing

2. Shorten suction lift and/or change head

3. Lower suction lift, install foot valve and prime,

or shorten length of suction line

4. Clean impeller

5. Repair or replace suction line, use pipe sealing

compound.

6. Match foot valve to piping or install one size

larger foot valve

7. Replace impeller

8. Submerge lower in water

9. Increase inlet pressure by adding more water to

tank or increasing back pressure

10. Increase to pump inlet size or one size larger

11. Check wiring diagram for correct wiring

12. Replace Gasket

13. Open suction and/or discharge lines

Pump will not deliver water or develop

pressure

1. No priming water in casing

2. Mechanical seal is leaking

3. Leak in suction line

4. Discharge line is closed and priming air has no

where to go

5. Suction line (or valve) is closed

6. Poor pump performance

7. Foot valve is leaking

8. Suction screen is clogged

1. Fill pump casing

2. Replace seal (See Rotary Seal Replacement)

3. Repair or replace

4. Open discharge line

5. Open suction line or valve

6. Replace worn parts

7. Replace foot valve

8. Clean or replace screen

Loss of suction

1. Air leak in suction line

2. Suction lift is too high

3. Insufficient inlet pressure or suction head in

booster system

4. Clogged foot valve or strainer

1. Repair or replace suction line

2. Lower suction lift, install foot valve and prime

3. Increase inlet pressure by adding more water to

tank or increasing back pressure

4. Unclog

Pump vibrates and/or makes excessive

noise

1. Mounting plate or foundation not rigid enough

2. Foreign material in pump

3. Impeller damaged

4. Worn motor bearings

5. Suction lift too high

1. Reinforce

2. Disassemble pump and clean

3. Replace impeller

4. Replace bearings

5. Lower suction lift, install foot valve and prime

Pump will not start or run

1. Improper wiring

2. Blown fuse or open circuit breaker

3. Loose or broken wiring

4. Stone or foreign object lodged in impeller

5. Motor shorted out

6. Thermal overload has opened circuit

1. Check wiring diagram on motor

2. Replace fuse or close circuit breaker

3. Tighten connections, replace broken wiring

4. Disassemble pump and remove foreign object

5. Replace motor

6. Allow unit to cool, restart after reason for over

load has been determined

Pump leaks at shaft

1. Worn mechanical shaft seal

1. Replace rotary seal (See Rotary Seal

Replacement)

Page 8

Download troubleshooting guide @ www.munrocompanies.com

Call Munro technical support for any questions relating to start-up or

operation of this pump.

Toll Free: 1.800.942.4270

Summary of Contents for LP 3 HP

Page 1: ...LP Manual Rev 0817 2017 MUNRO COMPANIES INC ALL RIGHTS RESERVED ...

Page 10: ......

Page 11: ......

Page 12: ......