14

Drive Belt

•

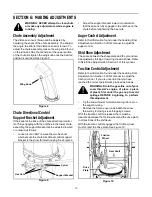

Follow the first four steps of the instructions for

servicing the auger belts.

•

Pull idler pulley up, and lift belt off engine pulley and

friction wheel disc. See Figure 17.

•

Back out the stop bolt until the support bracket

rests on the auger pulley. See Figure 19.

•

Slip belt between friction wheel and friction wheel

disc. See Figure 19. Remove and replace belt.

•

Reassemble following the instructions in reverse

order.

NOTE:

The support bracket must rest on the stop bolt

after the new belt has been assembled. See Figure 19.

Servicing Friction Wheel Rubber

The rubber on the friction wheel is subject to wear and

should be checked after 25 hours of operation, and

periodically thereafter. Replace the friction wheel

rubber if any signs of wear or cracking are found.

•

Drain the gasoline from the snow thrower.

•

Tip the snow thrower up and forward, so that it rests

on the housing.

•

Remove six self-tapping screws from the frame

cover underneath the snow thrower.

•

Remove the click pins which secure the wheels,

and remove the wheels from the axle.

•

Using a 7/8" wrench to hold the shaft, loosen, but

do not completely remove, the hex nut and bell

washer on the left end of gear shaft. See Figure 20.

Figure 20

•

Lightly tap the hex nut to dislodge the ball bearing

from the right side of frame before removing the hex

nut and bell washer from left end of shaft.

•

Move the gear shaft to the right and slide the friction

wheel assembly from the shaft.

Figure 21

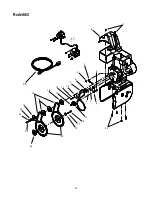

•

Remove the six screws from the friction wheel

assembly (three from each side). Remove the

friction wheel rubber from between the friction

wheel plates. See Figure 21.

•

Reassemble new friction wheel rubber to the

friction wheel plates and hub, tightening the six

screws in rotation and with equal force.

•

Position the friction wheel assembly up onto the pin

of the shift rod assembly, and slide the shaft

through the assembly. Reassemble in reverse

order.

Shave Plate and Skid Shoes

The shave plate and skid shoes on the bottom of the

snow thrower are subject to wear. They should be

checked periodically and replaced when necessary. To

remove the skid shoes, proceed as follows:

•

Remove the four carriage bolts, bell washers and

hex nuts which attach them to the snow thrower.

•

Reassemble new skid shoes with the four carriage

bolts, bell washers (cupped side goes against skid

shoes) and hex nuts. Make certain the skid shoes

are adjusted to be level.

To remove shave plate, remove the carriage bolts,

belleville washers and hex nuts which attach it to the

snow thrower housing. Reassemble new shave plate,

making sure heads of the carriage bolts are to the

inside of the housing. Tighten securely.

Augers

The augers are secured to the spiral shaft with two

shear bolts and hex lock nuts. Refer to Figure 14. If you

hit a foreign object or ice jam, the snow thrower is

designed so that the bolts may shear. If the augers will

not turn, check to see if the bolts have sheared.

IMPORTANT:

NEVER replace the auger shear bolts with

standard hex bolts. Any damage to the auger gearbox

or other components as a result of doing so will NOT be

covered by your snow throwers warranty.

Hex Nut /

Bell Washer

NOTE:

Snow thrower shown resting on its

auger housing. Wheels not shown for clarity.

Friction Wheel Rubber

Screws

Screws

Friction Wheel Plates

Hub