11

SECTION 7: MAINTENANCE

General Recommendations

•

Always observe safety rules when performing any

maintenance.

•

The warranty on this snow thrower does not cover

items that have been subjected to operator abuse

or negligence. To receive full value from the

warranty, operator must maintain the snow

thrower as instructed in this manual.

•

Changing of engine governed speed will void

engine warranty.

•

Some adjustments will have to be made

periodically to maintain your unit properly. All

adjustments in the Making Adjustments section of

this manual should be checked at least once each

season.

•

Periodically check all fasteners and make sure

these are tight

•

Follow the maintenance schedule given below to

get quality performance from your snow thrower

for a long time.

Lubrication

•

Lubricate pivot points on the control handle and

the extension spring at the end of the clutch cable

with a light oil once every season and before

storage of the snow thrower at the end of the

season.

Customer Responsibilities

MAINTENANCE SCHEDULE

P

R

O

D

U

C

T

E

N

G

IN

E

SERVICE DATES

B

ef

or

e

e

ac

h

us

e

A

fte

r

ea

ch

u

se

E

ve

ry

25

h

ou

rs

B

ef

o

re

st

o

ra

ge

O

nc

e

a

se

as

on

Lubricate pivot points

Clean snow thrower

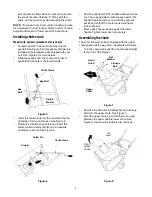

Check shave plate adjustment

Check belt

Clean engine

Check spark plug