USER MANUAL V2.0| Updated 01-Aug-2017

37

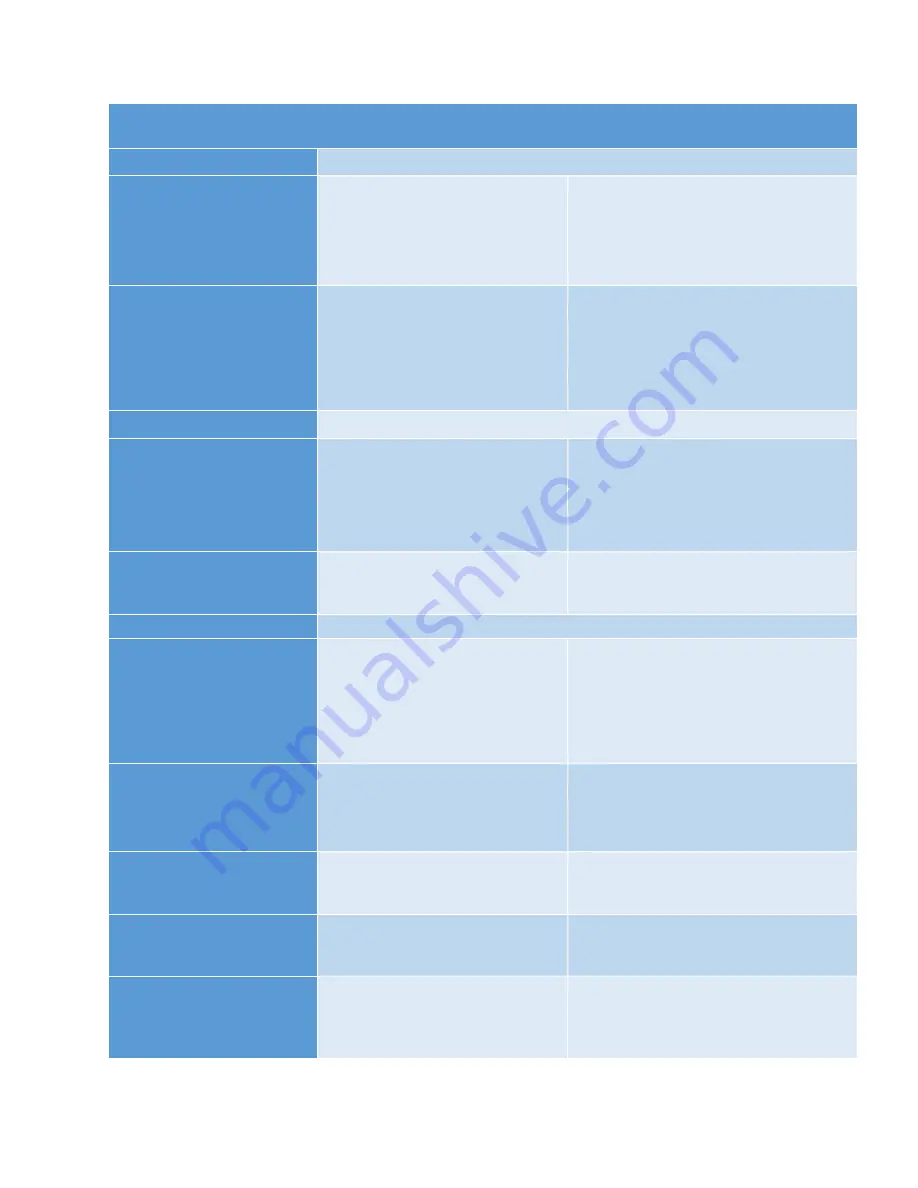

TROUBLESHOOTING

Error ID

Reason

Solution

Hardware

Display “Cartridge

connect fail”

The connection between the

boards on cartridge and

machine is not fully fitted or the

boards on cartridge is dirty.

Remove the cartridge, clear the

boards on cartridge and insert into

the machine again. If still display

“cartridge connect fail”, restart the

machine and check again.

Not print

The internal, external sensor is

dirty by ink and dusty. External

encoder is not connected with

machine (External encoder

mode).

Clear internal and external sensor.

Check connection between encoder

and machine.

Firmware

Distance , delay before,

delay after, fix length,

template ‘s length are

not correct

Setting encoder’s parameters

is not correct.

Change “

Pull / Resolution (PPR)

”

and “

Diameter of the Roller

”. Go to

HOME -> System setting

to

correct.

Update firmware is not

successful

Have error when check data

update.

Update firmware again.

Software

Can’t find the Wi-Fi

hotspot of machine

The machine was configured to

operate in Wi-Fi internet mode.

Not plug USB Wi-Fi or USB

Wi-Fi is not tight.

Check USB Wi-Fi and plug again to

machine and restart the machine.

If still can’t find Wi-Fi hotspot, hold

the button about 10 seconds to reset

default then restart the machine.

Can’t connect to

machine by web

browser or mobile

application

The connection of device and

machine is dropped.

Check the connection between

device and machine.

Machine is printing but

not update status.

The connection of device and

machine is dropped

Check the connection between device

and machine.

Not allow print when

enough two cartridge.

Two cartridge have different ink

type.

Change two cartridges have same ink

type.

Can’t connect to

machine after

configure the network.

Configure network for machine

is not correct.

Hold the button about 10 seconds to

reset default setting of the machine

and then restart.