Appendix

51

8

Appendix

8.1

Troubleshooting Guide

below to troubleshoot hardware and operating errors. The software version may be found in Help

About

Workbench.

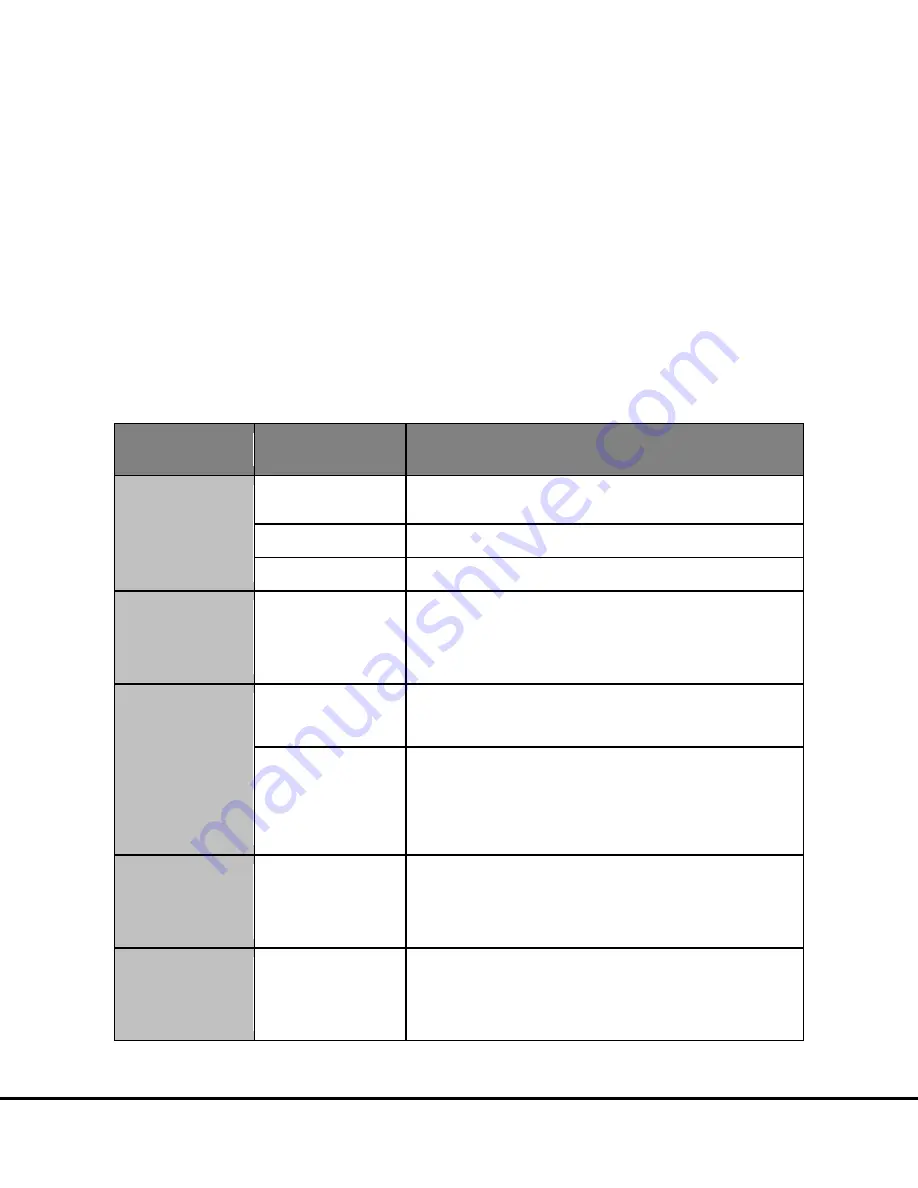

Table 8:1 Troubleshooting guide

Symptom/Error

message on screen

Possible Cause

Corrective Action

Instrument or computer does

not power on.

Loose or disconnected power

cable(s)

Ensure that the cables connecting the instrument and/or computer to the external power

source are plugged in properly.

No voltage at outlet

Test the outlet by connecting a different electrical device to the outlet.

One or more fuses activated

Fuse specifications for the instrument are shown in Section

The plate passes through the

instrument without being

read. The status window

jumps from 1% to 100%.

The instrument was unable to

read the barcode on the plate.

The bar code may be damaged,

smudged, marked, or otherwise

unreadable.

Verify a bar code is smoothly affixed to the side of the plate. Then, select the appropriate

plate type from the pull-down menu, and read the plate again. If the barcode is damaged,

reverse the orientation of the plate so that the barcodes on the other side of the plate are

read.

Error 515 General error

The instrument failed to read

the plate after clicking the

Run button.

Windows security settings,

networking parameters, or the

instrument name has changed.

Click OK to continue.

Determine whether your IT department has made any changes to the instrument computer

recently.

Incompatible anti-virus

software has been installed on

the instrument computer.

Disable the antivirus program temporarily to see if that is the issue. There are several

methods:

1)

Exclude the file: C:\Program Files\MSD Discovery Workbench\lib\prefs.properties

from scanning.

2)

Disable real-time scanning.

3)

Uninstall the antivirus program and use a different one.

Error 515 General error

The instrument failed to

initialize after clicking the

instrument icon.

The Windows theme has

changed.

Click OK to continue.

Restore the default Windows theme. Please check whether your IT department has made

any changes to the instrument computer recently.

The sysinfo file contains a software log that can be used to diagnose the problem. See

Section

for instructions on creating a sysinfo file.

Error 515 General error

The error was noted while

reading a plate or during data

analysis.

The Plate Data History

(database) is full.

Click OK to continue.

Backup and clear the database. For DISCOVERY WORKBENCH v4, instructions on backing

up and clearing the database can be found in the DISCOVERY WORKBENCH User’s Guide.

The software log will contain a message such as: Could not allocate space for object

'PIDTable' .....in database 'LCPRSchema' because the 'PRIMARY' filegroup is full.

Summary of Contents for MESO SECTOR S 600

Page 1: ...MESO SECTOR S 600 www mesoscale com USER MANUAL ...

Page 6: ...6 1 Introduction ...

Page 9: ...9 2 SafetyInformation ...

Page 19: ...19 3 SystemDescription ...

Page 33: ...33 4 Installation ...

Page 35: ...35 5 QuickStart ...

Page 43: ...43 6 UsingtheSECTORS600 ...

Page 47: ...47 7 Maintenance ...

Page 50: ...50 8 Appendix ...

Page 56: ...56 9 TechnicalSupport ...