RESPIRATOR USE

first aid procedures in case of overexposure,

decontamination, and handling and disposal of

contaminated equipment.

2. Each user should be quantitatively fit tested in the

facepiece they will be using and have a tested fit

factor of 1000 or greater.

3. It is recommended that each user should be outfit-

ted with a facepiece with CBA canister, a hood,

and full chemical protective suit including gloves

and shoe coverings.

4. The user would determine or check with the safety

office to verify that the protective equipment to be

used is sufficient for exposure to their particular

hazard and contamination level. Misuse of the pro-

tective equipment can result in serious personal

injury or death.

During the Stay in the CBA Contaminated Area

1. It is recommended that the area be real timed

monitored (with alarm) for exposure levels of the

contaminate. If the monitored contaminate level is

above the allowable exposure limit or maximum

use concentration (as determined by the governing

protocol), the user should leave the area immedi-

ately.

2. The user should not remove any of the CBA pro-

tective clothing while in the contaminated area.

This action could result in a serious injury or death.

3. If symptoms of CBA overexposure are present,

seek medical treatment and attention immediately.

After Exposure to a CBA Contaminated Area

1. A decontamination procedure for the user and the

protective equipment should be developed and

implemented.

2. Once the user leaves the contaminated area, they

should enter the decontamination area and follow

the set decon procedure. Failure to follow an

acceptable decon procedure could lead to serious

injury or death.

3. Once the user and the protective equipment have

been decontaminated, proper disposal of affected

equipment is to be performed. Disposal is to be

performed as required by federal, state and/or local

laws that apply to CBA contaminated materials.

Failure to follow accepted safety and protection pro-

cedures when exposed to hazardous atmospheres can

result in serious personal injury or death.

DECONTAMINATION

The PAPR may be used in some applications which may

require decontamination of personal and respiratory

equipment before the respirator may be removed.

Turn the motor-blower off before entering a decontamina-

tion shower.

If you are using a PAPR hood model, leave the motor-

blower on. Do not breathe through the respirator for

long periods of time with the motor-blower shut off.

CO2 can build up in the hood, causing serious person-

al injury or death.

CARTRIDGE CHANGE-OUT SCHEDULE

If a cartridge or canister with an appropriate ESLI is not

available, a change-out schedule based on objective

information or data that will ensure that the cartridge(s) or

canister is changed before the end of its service life, must

be developed and implemented.

Service time is the measured or estimated period of time

before breakthrough of an airborne contaminant (gas or

vapor) for a specific chemical cartridge under specified

conditions of the test.

The service time data presented in this investigation

applies only to MSA respirators. It should be used as a

guide only for determining an appropriate respirator car-

tridge change-out schedule as required for compliance

with OSHA’s Respirator Protection Standard (29 CFR

1910.134).

CBA HOOD

After Use

Remove and dispose of respirator in accordance with

local requirements.

Failure to follow the above warnings can result in seri-

ous personal injury or death.

12

TAL 209 (L) Rev. 1 - 10040590

WARNING

WARNING

Summary of Contents for OptimAir 6HC

Page 6: ...NOTES 6 TAL 209 L Rev 1 10040590 ...

Page 8: ...NOTES 8 TAL 209 L Rev 1 10040590 ...

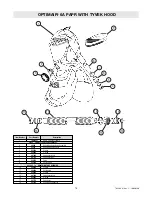

Page 15: ...15 TAL 209 L Rev 1 10040590 20 ...

Page 16: ......