7

5.7

Maintenance Intervals

Work to be

Intervals

performed

Prior to

each

use

After each

use

Semi-

annually

Every two

years

Cleaning, Disinfection

and Maintenance

X

X

Function and

Leak Test

X

X

Valve disc

replacement

X

Slide ring

replacement

X

Check by user

X

Zipper maintenance

X

X

The performed maintenance work should be noted

on the record card.

5.8

Repairs

Repair of suit material and seams as well as re-

placement of the zipper may only be performed by

the manufacturer or by authorized service centers.

Only original MSA AUER spare parts may be used

for repairs.

6

Maintenance Work

6.1

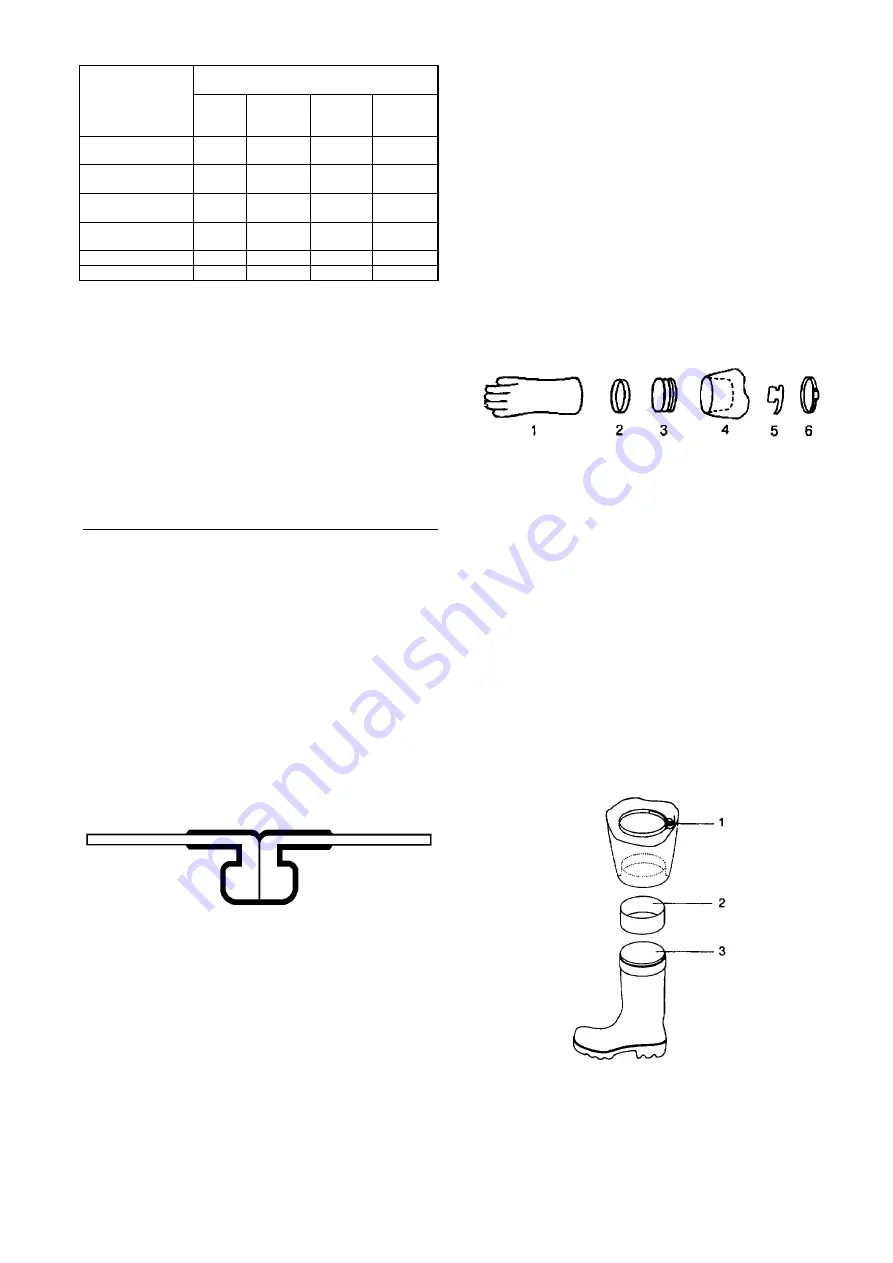

Suit Valves

In case of a leak either the valve disc or the entire

valve assembly must be replaced. To do this, the

threaded ring is unscrewed from the inside of the

suit using the key (see Ordering Information). Re-

gardless of the above measures, it is recommended

to replace the valve discs every 2 years at the latest

(Fig. 1).

6.2

Zipper

After each cleaning or disinfection the zipper is

treated with the grease pencil or zipper spray in

such a way that only a thin lubricant film covers the

metal links. See following figure for area to be lubri-

cated:

6.3

Replacing the Lens

Replacing the lens is done according to the Instruc-

tions for Use of the spare lens.

6.4

Replacing the Gloves

6.4.1 Disassembly of the Outer Gloves

x

Pull off cuff tube and the outer gloves.

6.4.2 Reassembly of the Outer Gloves

x

Pull outer glove over inner glove. The inner roll of

the outer glove must be fitted into the groove of

the ring. Afterwards replace cuff tube.

6.4.3 Disassembly of the Inner Gloves

x

Open zipper completely.

x

Turn sleeves of protective suit inside out.

x

Loosen clamp (6).

x

Pull out tube (3) with rubber ring (2).

Pull out glove (1).

6.4.4 Reassembly of the Inner Gloves

x

Insert tube into glove cuff.

x

Insert glove with tube into sleeve.

x

Align glove.

x

Fit clamp and tighten - torque: 400

r

30 Ncm

Caution!

Clamp lock must be on the same side as the thumb

and clamp protector must cover clamp lock.

x

Afterwards check protective suit for tightness.

Fig. 6

6.5

Replacing the Boots

6.5.1 Disassembly of the Boots

x

Remove cap tube on boot shaft

x

Completely open zipper of the protective suit.

x

Turn legs inside out.

x

Loosen and remove clamp (1).

x

Pull out tube (2).

x

Pull out boot (3) from suit leg.

6.5.2 Reassembly of the Boots

x

Push boot into suit leg that was turned inside out.

x

Align suit leg and boot.

x

Place tube into boot shaft.

x

Place clamp into position and tighten -

torque: 500

±

30 Ncm.

x

Fit cap tube on boot shaft

Fig. 7

Caution!

Clamp lock must be in the back and clamp protector

must cover clamp lock.

Afterwards check protective suit for tightness.