Summary of Contents for MQ POWER WhisperWatt DCA70USI

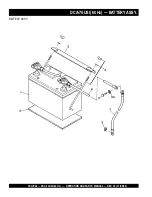

Page 2: ...PAGE 2 DCA 70USI 60 Hz OPERATION AND PARTS MANUAL REV 0 01 04 06 ...

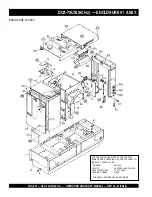

Page 20: ...PAGE 20 DCA 70USI 60 Hz OPERATION AND PARTS MANUAL REV 0 01 04 06 NOTE PAGE ...

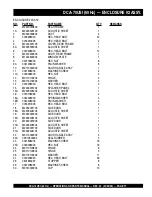

Page 47: ...DCA 70USI 60 Hz OPERATION AND PARTS MANUAL REV 0 01 04 06 PAGE 47 1 NOTE PAGE ...

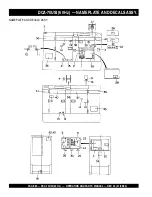

Page 83: ...DCA 70USI 60 Hz OPERATION AND PARTS MANUAL REV 0 01 04 06 PAGE 83 1 NOTE PAGE ...