DCA-150SSKII — PARTS AND OPERATION MANUAL— REV. #1 (05/08/01) — PAGE 47

WARNING:

Before Starting

Engine

1. Check the lubricating oil level prior to starting the engine.

Make sure the generator is level. The oil level must be

maintained between two notches on the dipstick.

2. When there is not enough lubricating oil, fill the crankcase

with high grade motor oil. Use a high quality detergent

oil classified CC or higher (See Table 12 on page 43).

3. Check the coolant level in the radiator and subtank.

Replenish with antifreeze as necessary. Always maintain

the coolant level between the FULL and LOW markings

on the coolant container. Be sure that the radiator cap is

fastened securely.

4. Check the fuel level on the fuel gauge. If fuel is low, fill

the fuel tank with clean fresh unleaded automotive diesel.

If diesel spillage occurs, completely wipe up the spilled

fuel immediately.

Before Starting

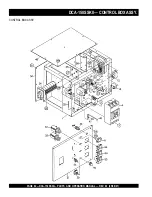

Generator and Control Panel

CAUTION:

1. Be sure to disconnect the electrical load and switch the

main, load and G.F.C.I. circuit breakers (Figure 42) to

the “OFF” position prior to starting the engine.

NEVER start the engine with the

main, GFCI or load circuit

breakers in the ON position.

The engine's exhaust contains

harmful emissions.

ALWAYS ventilate

the exhaust when operating inside

tunnels, excavations or buildings.

Direct exhaust away from nearby

Figure 42. Main, GFCI and

Load Circuit Breakers

DCA-150SSKII — GENERATOR START-UP PROCEDURE (MANUAL)

2. Once it is determined if commercial power is required,

connect the load to the UNV terminals as shown in

Figure 43. These terminals can be found on the output

terminal panel, see page 33, Figure 14. To gain access

to the output terminals lift the UNV cover. Make sure to

tighten terminal nuts securely to prevent load wires from

slipping out.

Figure 43. UNV Terminal Lugs (Load)

NEGA

TIVE

POSTIVE

BATTER

Y

3. Connect the negative battery cable (BLACK) to the

negative post on the battery (Figure 44).

Figure 44. Battery Connections