Page 2

The first letter identifies the material of the suction

housing.

C

—

Cast

Iron

E

—

Carpenter 20 Stainless Steel

H

—

Hastelloy

“C”

M

—

Monel

S

—

316 Stainless Steel

W

—

Cast

Steel

X

—

Special to application

Note: The bearing housing of the pump is always made

of cast iron.

The second letter indicates the material used in the

drive shaft, connecting rod, rotor and other wettable parts.

D

—

Alloy

Steel

E

—

Carpenter 20 Stainless Steel

G

—

416 Stainless Steel

H

—

Hastelloy

“C”

J

—

17-4 PH Stainless Steel

M

—

Monel

S

—

316 Stainless Steel

X

—

Special to application

The third letter indicates the material of the stator. It identi-

fies only the stator material and not that of the tube in which

the stator is placed, which is always carbon steel. Standard

stator materials used in the Moyno 2000 pump are as fol-

lows:

B

—

EPDM 300, 70 Durometer

C

—

Nitrile 103, 50 Durometer

D

—

Tool

Steel

E

—

Nitrile 110, 70 Durometer

F

—

Fluoroelastomer 500, 75 Durometer

G

—

416 Stainless Steel

H

—

Hastelloy

“C”

J

—

17-4 PH Stainless Steel

K

—

Hypalon 800, 70 Durometer

M

—

Nitrile 100M 70 Durometer

P

—

Thiokol 70 Durometer

Q

—

Nitrile 100, 70 Durometer

R

—

Natural Rubber 200, 55 Durometer

T

—

Teflon 15% glass

U

—

Urethane 70 Durometer

X

—

Special to application

Z

—

White Nitrile 150,70 Durometer

A typical type designation such as CDQ, would identify the

following materials of construction:

C

=

Cast iron suction housing

D

=

Alloy steel rotor, drive shaft, connecting

rod and other minor metallic parts in con-

tact with the fluid being pumped.

Q

=

Nitrite (70 durometer) stator

1-8. Trim Code.

Also included in the Model Number is the

three character Trim Code which is used to identify pump

construction. The letters “AAA” signify standard construction,

with letters other than “A” signifying variations. The first letter

identifies sealing variations; the second, internal variations;

and the third, rotor variations.

1-9. Variations of Standard Parts.

Refer to Sections 4-55

thru 4-57 for variations available for modifying pumps to

meet specialized pumping conditions. If the trim code of your

pump is other than “AAA,” contact your nearest Moyno rep-

resentative for clarification. Do not modify your pump with

any variation unless you have determined that it is compat-

ible with your application.

2-1. INSTALLATION

2.2. GENERAL

Moyno pumps are lubricated and tested at the factory

prior to shipment and require minimum pre-start up

maintenance.

Accessibility to the pump and adequate clearance should

be a prime consideration in any installation. Enough space

should surround the unit so that maintenance can be car-

ried out with ease.

2-3. PIPING

2-4. Suction hopper

used with open throat and bridge

breaker pumps should have nearly vertical sides, or be oth-

erwise designed to enhance the flow of the material into the

pump.

2-5. Discharge piping

diameter should generally be as

large as the pump ports unless fluid conditions indicate

otherwise.

An easily removable section of piping one-to-two times

longer than the connecting rod should be mated to the dis-

charge port. This will allow the rotor and stator to be re-

moved without having to remove the complete pump from

the base.

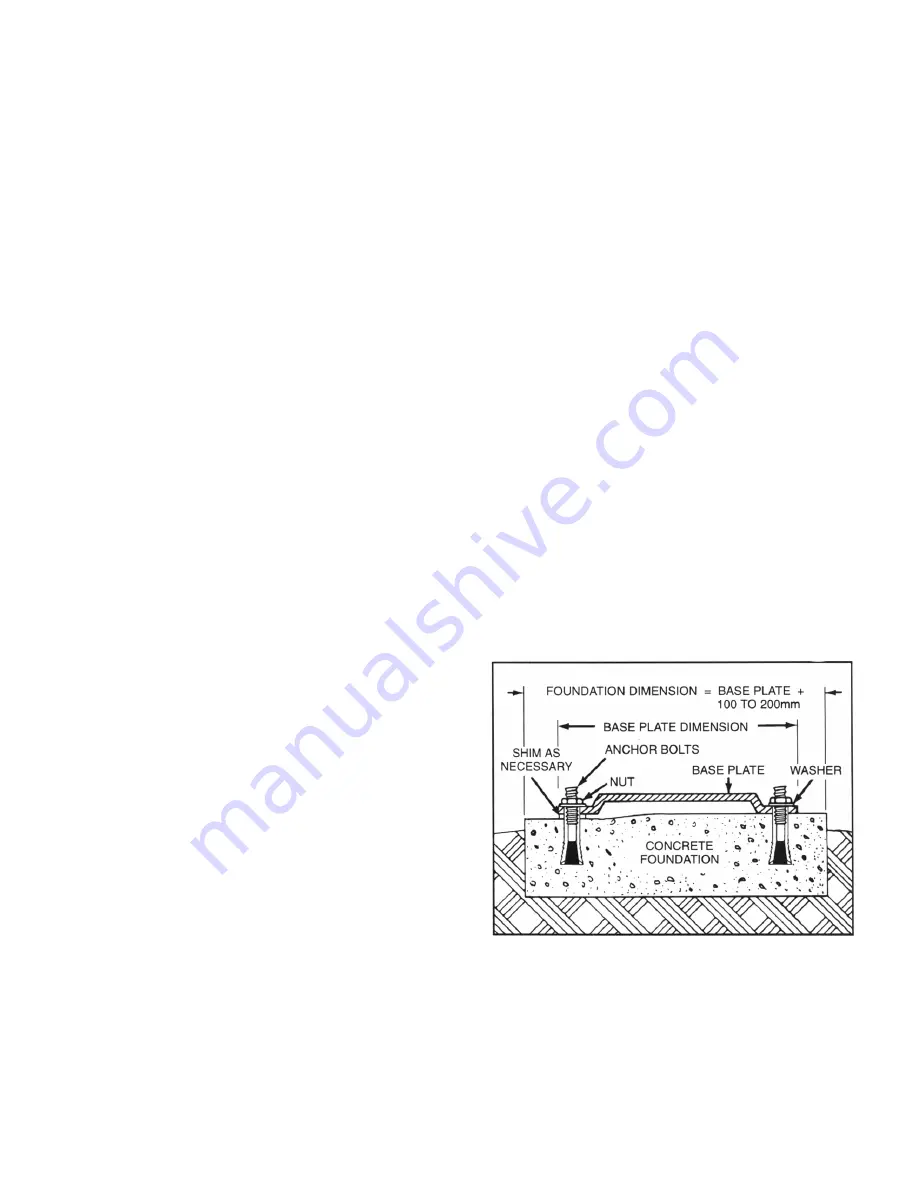

2-6. FOUNDATION

For maximum pump-driver unit life, each unit should be

mounted on a strong, fabricated-steel base plate which can

be ordered from Moyno. The base plate should be mounted

on a concrete foundation built on a solid base. The foundation

should be approximately 4” to 8” longer and wider than the

base for which it is built. (See fig. 2-1.) Anchor bolts for the

base plate should be located in the foundation.

Figure 2-1. Typical Foundation Example

Check the base plate surface with a carpenter’s level

and place shims under the base plate at the places

necessary to make it level. Then check the pump,

driver shaft and the pump ports to ensure that they are level.

Complete base mounted units supplied by Moyno including

pump and driver are leveled with respect to the base at the

factory. Shifting may occur during shipment. The pump and

driver should be realigned. Care should be exercised to en-

sure that all components are level and mounted in a direct line.

Summary of Contents for Version 3

Page 1: ......

Page 19: ...Page 16 4 60 PARTS LIST FOR G2 OPEN THROAT Table 4 1 G2 Parts List ...

Page 20: ...Page 17 FOLD OUT FOR EXPLODED VIEW OF PUMP Notes ...

Page 21: ...Page 18 ...

Page 22: ...Page 19 Figure 4 7 G2 open throat pump exploded view ...

Page 26: ...Page 23 Figure 4 10 G3 bridge breaker exploded view ...

Page 28: ...Page 25 ...