An awning is subject to some adverse situations: humidity, sea breeze, counterweight, wind ...

We recommend that:

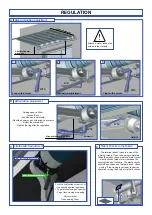

Check the tightening of the screws and the limit switch after installation and regularly at the beginning and end of each season.

Never close a wet awning. Dry it if possible.

Clean the fabric and the frame at the beginning and end of each season. Caution: never use detergents.

The limit switch inclination and regulation (for awnings with eléctrical

maneuvers) are pré regulated during the use. They are

susceptible to be modified for use as shown in regulation.

A small flexion of the terminal could happen (4 to 5 cm). It is related with the arm main impulse and the fabric may be loose in

the central area .

A small difference of fabric fibers could be detected between two awnings when they were not acquired at the same time.

Folds or other effects may appear on the fabric. This not decrease away from the quality and effectiveness of the awning.

Ripples may appear on the fabric due to excess thickness caused by seams and hems which cause tensions on the winding

tube.

Use the emergency operation only in the event of a power failure, to close the awning. Using the emergency operation at

presence of energy will deregulate the motors’s limit switch end of the engine stroke. After using the security operation, make

sure the handle is in the spare outlet axis.

For electrical installation with an unstable switch, make sure you leave it in stop position after each use.

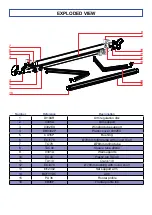

The awning balcony disintegrated

from the structure.

Screws are not the most appropriate.

Check proper placement of the supports (according to

the manual's instructions)

In case of fixing with a chemical seal, report to the

manufacturer.

INFORMATION TO THE CONSUMER

To know :

Problems

Causes

Solutions

Fabric deformation. (Natural effect)

EN 13561 table ZA.1 Exterior

awning

Wind resistent

Awning width

4

4.8

5

5.98

2

2.25

2.5

2.75

3

Awning progress

CLASS 2

CLASS 1

CLASS 0

Don’t install in case of:

Rain

Wind

Snow

Nothing suspended

Awning maintenance advice

The fabric is not leveled.

The front profile is not closed the

entire length.

Fabric deformation after several uses.

Bad regulation of the front profile or the arm

articulation.

Check the level of the mounting brackets. Repeat

fixation with a level.

Check the level of the front bar. Rectify the adjustment

of arm inclination. (paragraph A)

Motor limit switch regulation. (paragraph C)

Articulation adjustment (paragraph B)

Proceed to plástic chocks installation. (paragraph D)

Wait until the protection’s end (20 minutes).

Check the motor connection.

Check engine operation by connecting directly to the

power input. (black or brown blue blue).

Connection problem.

Electric awning maneuvers do not

work.

The front profile is not closed on one

side.

Electric awning maneuvers do not

work.

The engine is placed in thermal protection after 2

descents and a 1 rise successives.