5

Installation/Owner’s Manual 20201109

For Warranty Service Call 833-474-0367

•

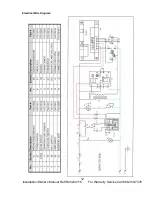

Air supply and ventilation:

The area in front and around the appliance must be kept clear to avoid

any obstruction of the flow of combustion and ventilation air. Adequate clearance must be

maintained at all times in front and at the sides of the appliance for servicing and proper ventilation.

•

Pressure Regulator:

All commercial cooking equipment must have a pressure regulator on the

incoming service line for safe and efficient operation. The internal regulator provided for this

appliance is adaptable for both Natural Gas and Liquefied Propane (LP) Gas. A conversion kit with

separate instructions is included explaining this procedure in detail.

•

Regulator information:

Internal p

ressure regulator is factory adjusted for four (4”) inch Water

Column (WC) Natural Gas standard and may be converted by qualified personnel to be used for

Propane at ten (10”) Water Column pressure.

•

Prior to connecting the gas line, check the

incoming line pressure. The internal regulator

can only withstand a maximum pressure of ½

PSI (14” WC). If the line pressure is beyond

this limit, a step down regulator before the

convection oven will be required. The arrow

shows gas flow direction.

•

Gas Connection:

The serial plate is

located outside on the right panel near the

front top. It indicates the type of gas the unit is

equipped to burn. All our equipment is

adjusted at the factory. Check type of gas on

serial plate. The appliance comes fitted with a

¾” NPT (National Pipe Thread) male adapter for connection. The appliance is design-certified for

operation on natural or propane gases, it should be connected only to the type of gas for which it is

equipped.

•

Maintenance

: A qualified service company should check the unit for safe and efficient operation on

an annual basis. Contact the factory representative or local service company to perform

maintenance and repairs.

•

Gas Piping:

Gas piping shall be of such size and so installed as to provide a supply of gas sufficient

to meet the full gas input of the appliance. If the appliance is to be connected to existing piping, it

shall be checked to determine if it has adequate capacity. Joint compound (pipe dope) shall be used

sparingly and only on the male threads of the pipe joints. Such compounds must be resistant to the

action of Liquefied Propane (LPG) gases.

Manual Shut Off Valve:

A manual shut off valve should be installed upstream from the manifold, within four

(4) feet, (1.2M) of the appliance and in a position where it can be reached in the event of an emergency.

Checking For Gas Leaks:

Using a gas leak detector or a soapy water solution is recommended for locating

gas leaks. Check entire piping system for leaks.

DO NOT USE AN OPEN FLAME

Matches, candle flame, or

other sources of ignition shall not be used for this purpose of checking for gas leaks

Any loose dirt or metal particles, which are allowed to enter the gas lines on this appliance, will damage

the valve and affect its operation. When installing this appliance, all pipe and fittings must be free from

any internal contaminates. It is recommended that a “drip leg” be installed in-line before the regulator.