26/03/19 CD4M9010_EN

M

31

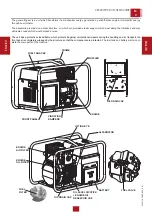

COMANDI - CONTROLS - COMMANDES - MANDOS - BEDIENELEMENTE - COMANDOS

СИСТЕМЫ УПРАВЛЕНИЯ - BEDIENING

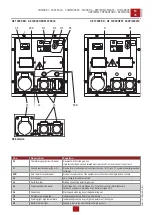

Pos.

Description

Function

Z2

Thermal-magnetic circuit breaker

General switch for the gen-set.

It protects both gen-set and related electrical circuit from over current /short circuit.

D

Ground fault interrupter (30 mA)

Device for protection against not-direct contacts for TN and TT systems (neutral grounded

to frame)

59B

AUX thermal circuit breaker

Overcurrent protection of the equipments connected to the single-phase sockets

15

A.C. socket

AUX sockets for load connection.

12

Earth terminal

Ground connection point for gen-set.

Z6

Digital multifunction meter

GE voltage VAC - GE Hz Frequency - Total hour counter - Resettable split

time hour counter (for maintenance) - Battery voltage VDC

Q1

Starter key

Starting and stopping key of the generating set.

O1

Oil pressure warning light

Indicates engine stop due to low oil pressure.

F5

Warning light, high temperature

Indicates engine stop due to high temperature of the engine.

N1

Battery charger light

Signals a fault in the motor battery charging circuit.

Z6

N1

Q1

F5

59B

15

12

15

Z2-D

O1

Z2

D

CEE version

REV

.1-09/19

GE 10000 KD - GE 10000 HZDM 230Vx3

GE 12000 KD - GE 12000 HZDT 400V/230Vx2

Summary of Contents for CD4R90119003

Page 2: ......

Page 33: ...11 01 01 Note NOTE 34...

Page 34: ...11 01 01 Note NOTE 34...

Page 35: ......