The Specialist In Drum Handling Equipment

Model 82AM

Mobile-Karrier / Palletizer

with Spark Resistant Parts

Operator’s Manual for Model 82AM Morse Mobile-Karrier / Palletizer with Spark Resistant Parts

Serial number 0212 to 0213 (MMYY)

morsedrum.com

Copyright 2019 - Morse Mfg. Co., Inc.

Form PL82AM (0212-0213)

(Updated 24 May, 2019 11:58 AM)

4

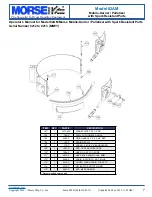

Controls

The Morse Hydra-Lift Karrier is manually propelled and steered.

There are two functions for the operator to control:

“LIFT” and lower function for vertical positioning of the drum

1.

“TILT” function to control the degree of rotation of the drum

2.

LIFt and Lower Function

(Figure 2.3)

To raise the drum

Insert pump lever handle into pump socket.

1.

With the release valve closed, begin to pump the lever handle. The drum

2.

will lift.

To lower the drum

Open the release valve slowly, a part of a turn. Allow the drum to descend at a

controlled rate. The valve may be reclosed to hold the drum at any height.

tILt Function

To tilt the drum

Either one of the two spring loaded plunger tilt-locks may be locked to

1.

hold the drum upright. It is not necessary to lock both of them.

Position drum at pouring station.

2.

Before unlocking the tilt-lock(s) to permit tilting the drum, it is

3.

recommended that you steady the drum and be prepared for its possible

tendency to tilt toward its heavier side.

With both tilt-locks unlocked, manually tilt the drum for pouring. The drum

4.

pouring angle may be varied or it can be locked in horizontal position by

one of the tilt-locks.

WARnInG:

Keep hands and fingers clear of tilt lock hole, as a pinch point will occur when drum rotates.

Figure 2.3