RANGE FGRi

MORELLO FORNI S. A. S.

11

3.5

TECHNICAL DATA

3.6 PREPARATION OF THE OVEN

The oven is a combustion model and must therefore be installed in adequately ventila-

ted areas or following the requirements specified in the current standards of competent

bodies.

3.7 OPERATING CHARACTERISTICS

The ovens manufactured by Morello Forni are preset to work with the type of gas spe-

cified in the order. To be able to use them with gases that are not specified on the table

supplied with the oven, it is first necessary to adapt them.

3.8 ADAPTING THE OVEN FOR ANOTHER TYPE OF GAS

This operation, which implies replacing the nozzles of the burner, must be performed

by a qualified and trained technician who will also have to annotate the new operating

characteristics of the oven after the applied changes. To request this kind of operation,

always refer to a qualified servicing technician of the manufacturer or an authorized dea-

ler.

AVOID TURNING THE OVEN ON IF THE OPERATING CHARACTERISTICS

DIFFER FROM THOSE STATED IN THE TEST TABLE SUPPLIED WITH IT!

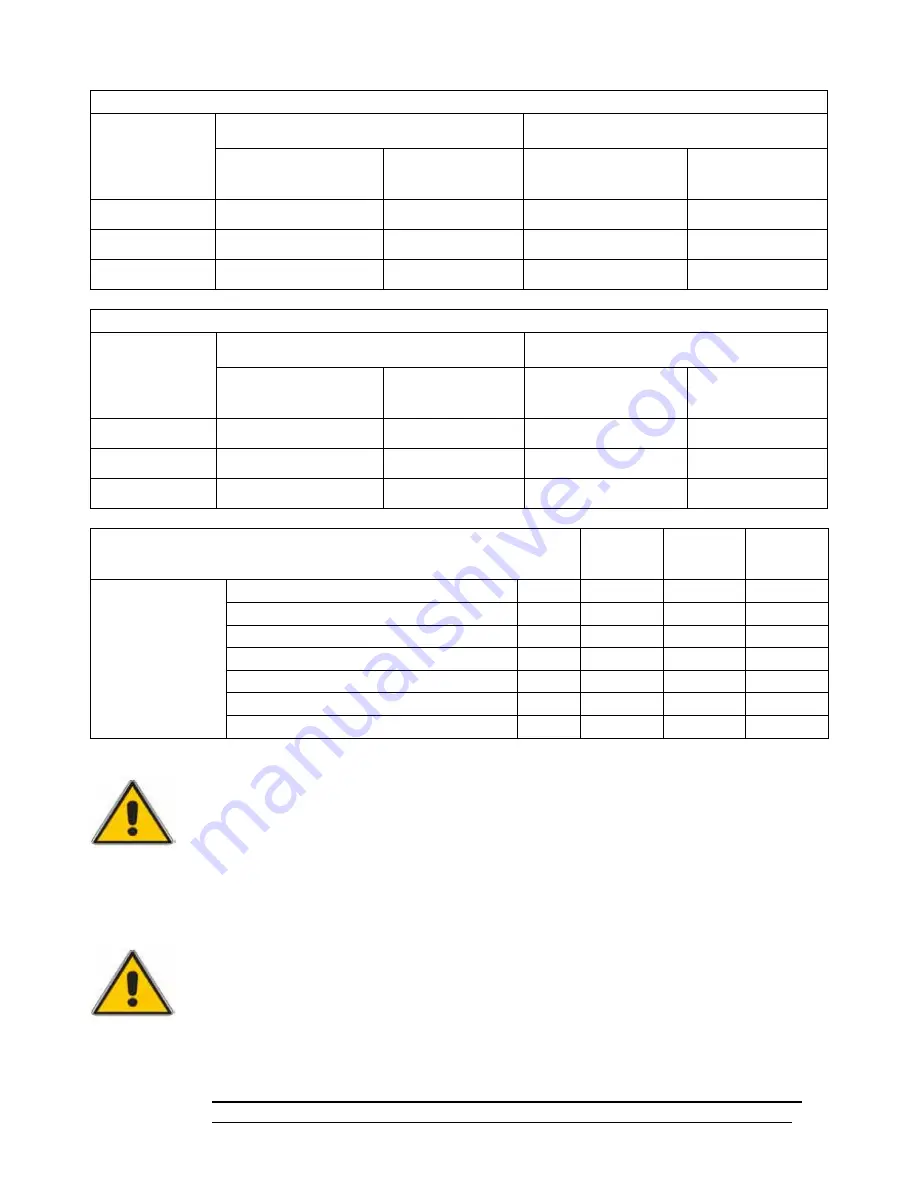

BURNER ON THE BEDPLATE

Ref. / Mod.

DIAMETER OF BURNER

NOZZLE: 1/100 mm

POSITION OF MAIN AIR NOZZLE ON

MAIN BURNER: “X” mm

LIQUID GASG30/G31/

30/37 mbar

NATURAL GAS

G20 (20 mbar)

G25 (25 mbar)

LIQUID GASG30/G31/

30/37 mbar

NATURAL GAS

G20 (20 mbar)

G25 (25 mbar)

FGRi 100

1 X 200

1 X 280

6

8

FGRi 110

1 x 250

1 x 300

6

8

FGRi 130

2 X 160

2 X 260

2 X 10

2 X 10

BURNER ON THE DOME

Ref. / Mod.

DIAMETER OF BURNER

NOZZLE: 1/100 mm

POSITION OF MAIN AIR NOZZLE ON

MAIN BURNER: “X” mm

LIQUID GASG30/G31/

30/37 mbar

NATURAL GAS

G20 (20 mbar)

G25 (25 mbar)

LIQUID GASG30/G31/

30/37 mbar

NATURAL GAS

G20 (20 mbar)

G25 (25 mbar)

FGRi 100

3 x 150

3 x 250

3 x 8

3 x 10

FGRi 110

3 x 160

3 x 260

3 x 8

3 x 10

FGRi 130

4 x 150

4 x 250

4 x 10

4 x 10

Ref./ Mod.

FGRi 110 FGRi 130 FGRi 150

Nominal Heat

Mass of testing of fuel per hour

Kg/h

2,846

3,588

4,273

Average temperature exhaust gas

°C

151,35

153,75

157,62

exhaust flux

m

3

/h

314,60

396,824

472,39

Average satisfied CO at 13%O

2

%

0,188

0,2377

0,282

Absorbed heat

Kw

12,78

16,12

19,19

Nominal Heat delivered

Kw

3,91

4,94

5,88

Efficiency at nominal heat delivered

%

24,30

30,66

36,49