Immunity from external interfering radiation is dependent on

careful wiring techniques. The accepted method is to use

screened cables for all connections and to radially terminate

the cable screens, in an appropriate grounded cable gland, at

the point of entry into the industrial steel enclosure. If this is

not possible, chassis ground screw terminals are provided on

the G123-814. Exposed wires should be kept to a minimum

length. Connect the screens at both ends of the cable to

chassis ground.

5 Power supply

24V nominal, 22 to 28V

45mA @ 24V without a load.

If an unregulated supply is used the bottom of the ripple

waveform is not to fall below 22V.

6 Input signal

The input command is 0 to ±10V. Input resistance is 100k

Ohm. An input of 0 to +10V causes a proportional current of

0 to 1 Amp in coil A. 0 to –10V causes a proportional current

of 0 to 1 Amp in coil B. These outputs result from the input

connected to the positive terminal. Connecting the input to

the negative terminal reverses the outputs. Connect the

unused input to signal ground (terminal 7). Connect the input

signal ground to the signal ground of the device supplying the

input signal.

7 Outputs

Both sides of each valve coil must be wired back to the G123-

814. Do not place any diodes across the coil. See paragraph

3.3 for advice on cable size.

8 Enable input

The output current drivers will not deliver current to the valve

coils until the enable input has a voltage of between 10 and

24V connected to it.

11 Front panel indicators

The “cmd” (command) LED indicates the polarity and level of

the input signal. Red is positive and green is negative.

The IA and IB LEDs indicate the level of the corresponding coil

current.

12 Withdrawing the circuit card

from its case

If access to the circuit is required, the circuit card needs to be

withdrawn from its case. To do this, push one tab in with a

pen or screwdriver while gently pulling on the top cover on

that side. The cover will release approximately one mm. Repeat

on the other side and withdraw the cover and circuit card until

the required circuit points are exposed. The rigidity of the

connecting wires will hold the circuit card in position while

measurements are made.

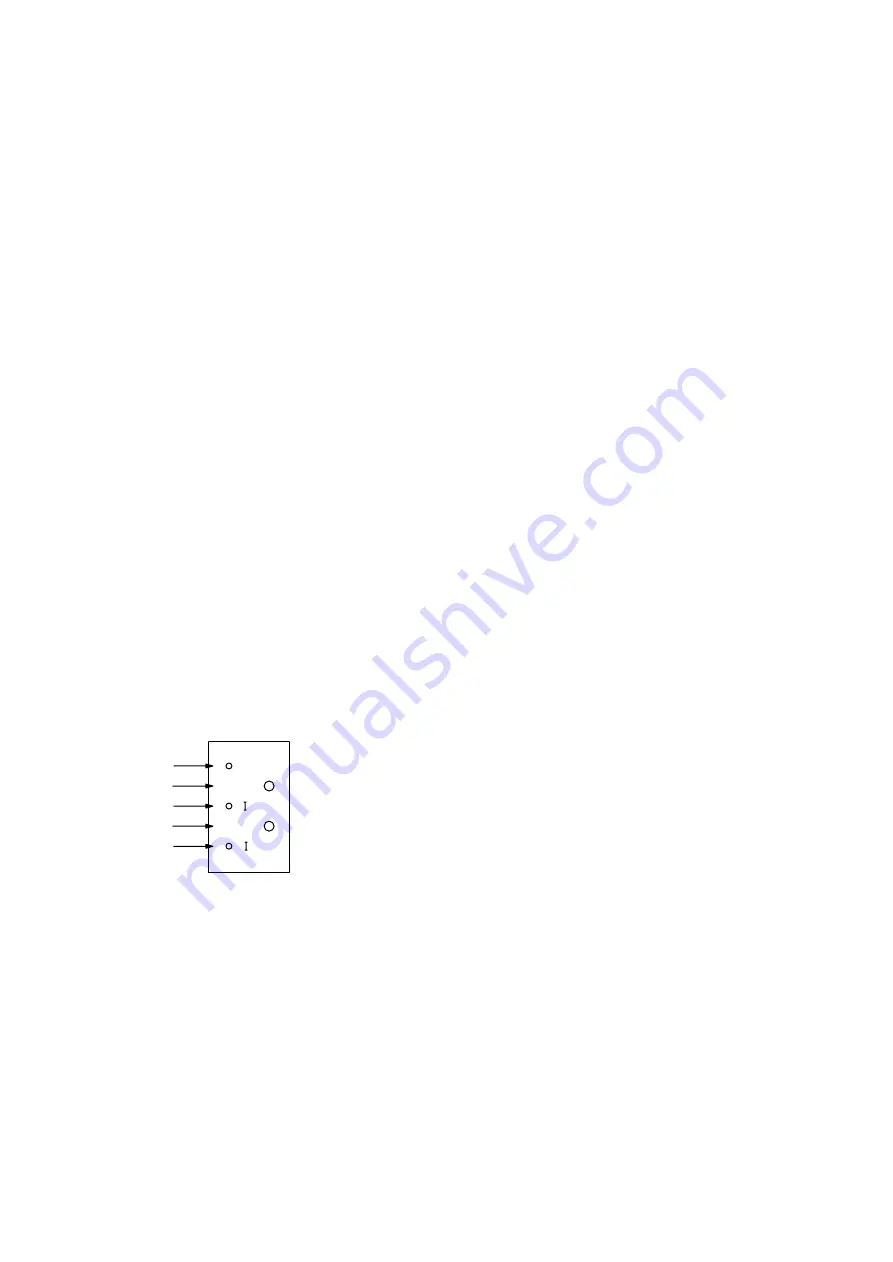

MOOG

cmd

zero

A

dither

B

dual PWM

LED

LED

LED

POT

POT

9 Dither

The front panel dither pot allows up to 100mA of 100Hz

dither to be superimposed on both coil currents. Dither is used

to overcome resolution limitations of the proportional valve

and is normally used if performance is being compromised by

the resolution of the valve. Optimum dither is achieved by

firstly increasing the level until it can be detected in the load

(the controlled variable, such as position). When this condition

is reached, reduce the level until its influence is just

undetectable in the load.

10 Zero

The zero pot allows up to 150mA coil current offset. Clockwise

rotation increases the offset to coil A. With your desired zero

input signal adjust the zero pot for the desired valve output

flow.