Page 6

L38DF-ST See-thru Indoor Gas Fireplace

Part No. XG0810 - 092109

f i r e f e a t u r e

Installation

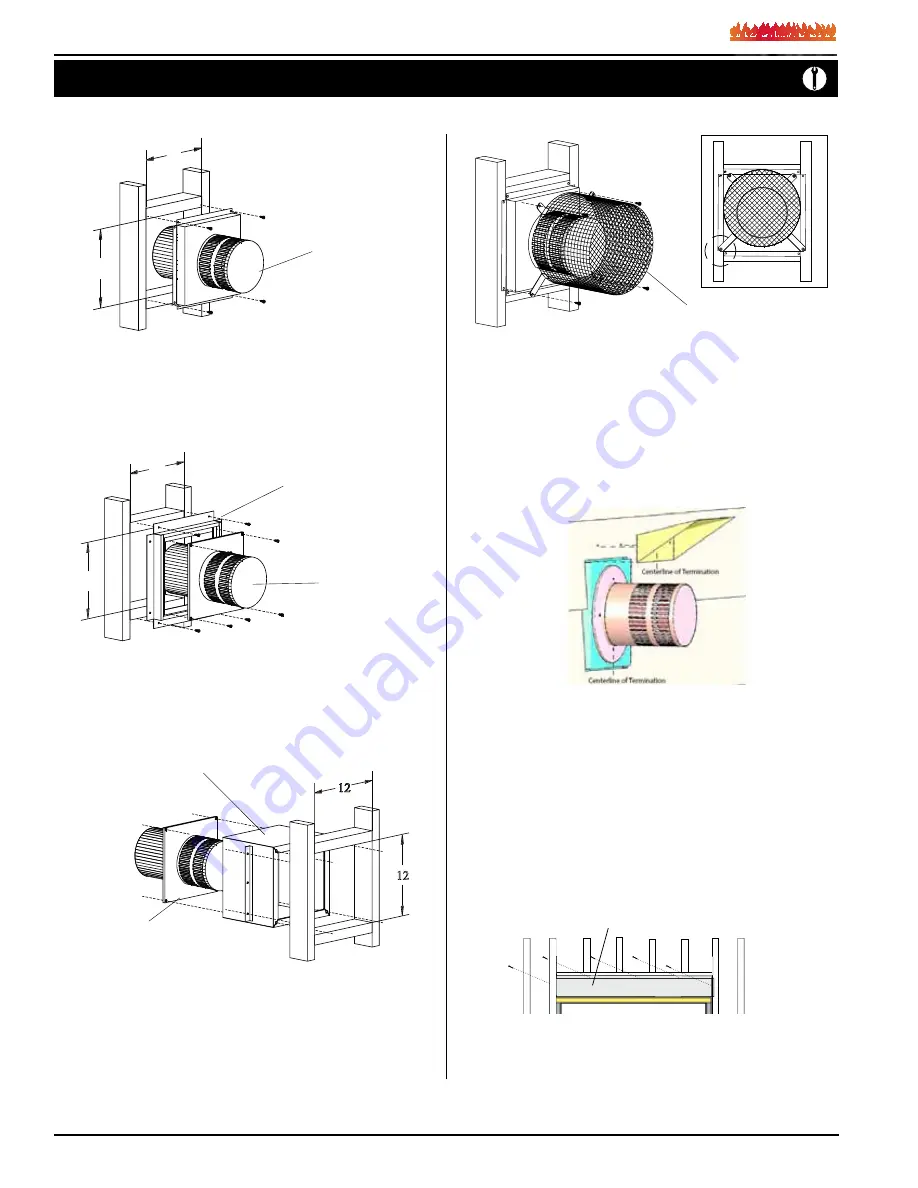

Installing Terminations with Built-In Frames

Installing Terminations with MSR Frames

12

12

1. Frame the termination opening to 12" x 12".

2. Fasten the termination to the studs using a minimum of 4 screws.

11

11

1. Frame the termination opening to 11" x 11".

2. Fasten the termination to the studs using a minimum of 4

screws.

Installing Terminations with MOSR Frames

12

12

12

MOSR

1. Frame the termination opening to 12" x 12".

2. Fasten the MOSR frame to the interior side of the studs using a

minimum of 4 screws.

3. Insert the termination into the MOSR frame as shown here, and

attach by screwing through the four pilot holes in the termination.

MSR

PTO-3 (5"/8")

PTO-3F (5"/8")

PTO-3 (5"/8")

PTKOG

(5"/8")

1. Ensure that the two

long

mounting brackets are facing the bottom

of the termination. (See inset). This will provide more heat protection

at the top of the termination, where temperatures are highest.

2. Attach to the faceplate of the termination using four sheet metal

screws.

3. If installing the termination over Vinyl siding, Use the VSS Termination

shield.

Montigo Installation document, XG1301

.

Installing Heat Guards over Terminations

Figure 6c.

Installing the Nailing Flange Extension.

Figure 6.

Installing the VSS Vinyl Shield.

Figure 5a.

Installing a PTO termination.

Figure 5b.

Installing a PTO termination with the MSR frame.

Figure 5c.

Installing a PTO termination with the MOSR frame.

Figure 5d.

Installing a PTO termination heat guard.

Installing the Nailing

Flange Extension

Once the fireplace is placed into the rough framed opening, and the

supplied steel lintel is in place, (Part No. L38087) (see Figure 6c),

the supplied nailing extension must be placed along the top edge of

the fireplace and securely fastened in place to the metal lintel, and

combustible wood framing. Note: The nailing flange extension can be

substituted with a piece of NON-Combustible material of the same

size and thermal characteristics, ie: cement board or equivilent.

Part No. L38087