Technical service manual

17

UK

(as described in the relative paragraph).

- Disconnect the connector on the search circuit board and the pick up cable on the

motherboard.

- Unscrew the three fixing screws on the beam and remove the central unit.

- Fit the new central unit. The three fixing screws must be tightened to a torque of 48 Nm.

- Replace the search circuit board complete with support.

- Reconnect the pick up and search board connectors.

- Replace the motor complete with support and adjust the wheel spin device.

- Replace the sensor, reversing the operations carried out to disconnect it.

- Calibrate the sensor as described in the operator’s manual.

- Perform a few wheel spins and check that the wheel spin device is operating correctly.

- Perform sensitivity calibration both in CAR environment (with a car wheel) and in

TRUCK environment (with a truck wheel).

ADJUSTING THE WHEEL SPIN DEVICE

- Open the weight-holder lid, first undoing the fixing screws.

- Undo the lock-nut (D, fig. 3) which fixes the adjuster washer (A, fig. 3).

- Completely tighten the adjuster check nut (D, fig. 3). This eliminates the preload of

the spring (B, fig 3).

- Undo the screws which fix the motor support (C, fig. 3) to the beam underneath.

- Position the motor unit so that the drive roller and the pulley are about 4-5 mm apart

and the axis of the motor is parallel to that of the central unit.

- Tighten the screws which fix the motor support.

- Preload the spring (B, fig. 3), unscrewing the check nut (D, fig. 1); until the gap be-

tween the drive roller and the pulley has been reduced to 2 mm.

- Tighten the lock-nut.

- The wheel spin device has a limit stop screw which dampens the residual oscillations

of the drive unit at the end of the wheel spin phase.

Adjust the limit stop as follows:

• position the screw so that it is not touching the leaf spring;

• make sure that the drive unit is in the rest position (drive roller 2 mm from the pul-

ley);

• tighten the screw until it slightly preloads the leaf spring of the motor support;

- Perform a few trial wheel spins and check that the wheel spin device is operating cor-

rectly.

- Close the weight-holder lid again.

- If the screw (E, Fig.3) does not slide freely when activating the cylinder, turn the nut

(F, Fig.3).

Summary of Contents for MT 2450

Page 1: ...MT 2450 Code 4 131046_uk 12 2013 Technical service manual...

Page 25: ...Technical service manual 25 UK Note...

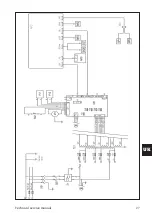

Page 27: ...Technical service manual 27 UK...

Page 28: ...28 Technical service manual...

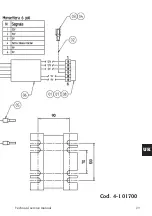

Page 29: ...Technical service manual 29 UK Cod 4 101700...

Page 30: ...30 Technical service manual...

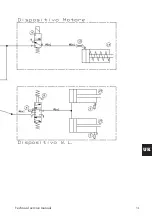

Page 31: ...Technical service manual 31 UK...

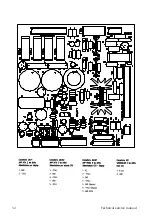

Page 32: ...32 Technical service manual...

Page 33: ...Technical service manual 33 UK Cod 457674B...

Page 34: ...34 Technical service manual...