AT-1992 Hand Crimp Tool

Doc No:ATS-640070100

Release Date: 10-03-02

UNCONTROLLED COPY

Page 11 of 15

Revision: J

Revision Date: 08-08-13

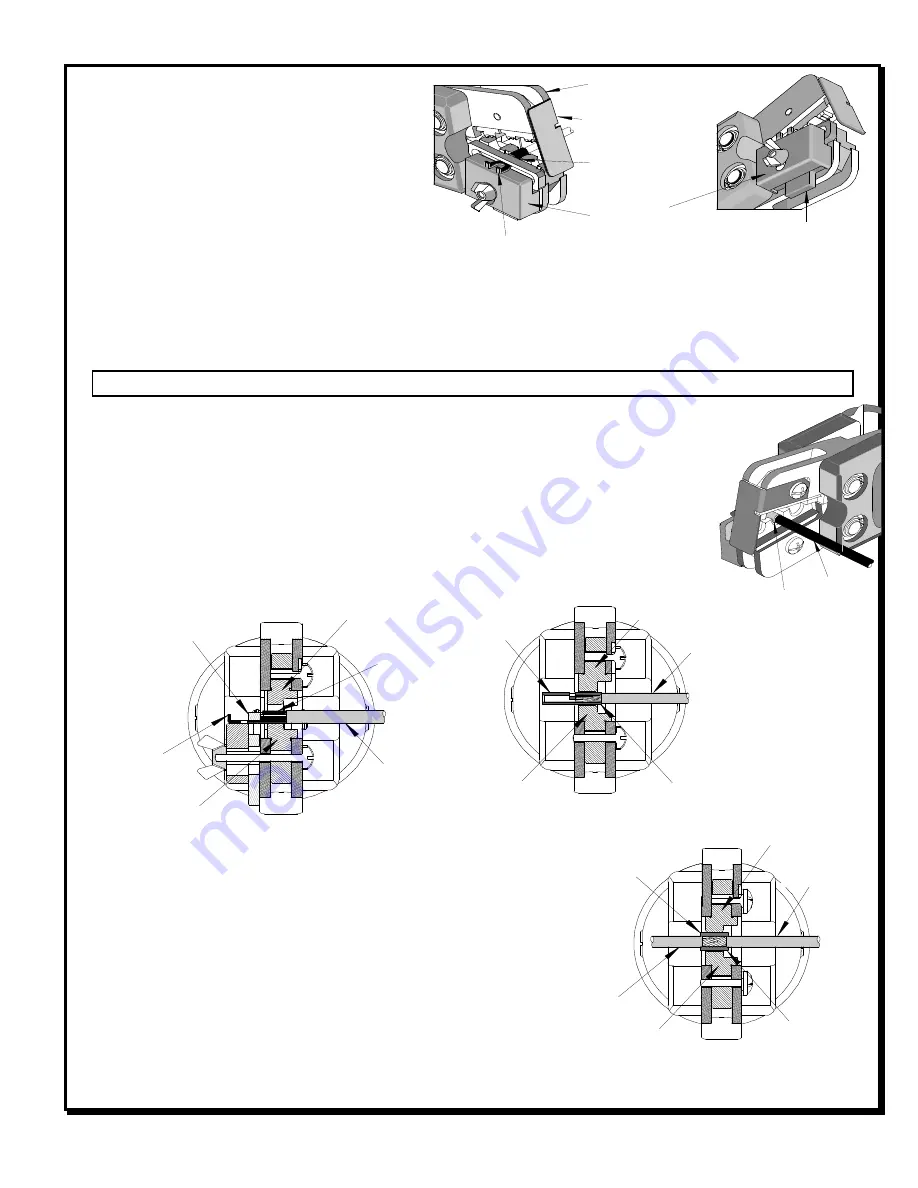

Figure 1

JAWS OPEN

SAFETY

SHIELD

FRONT EDGE

OF BARREL

LOCATOR

PUSH UP TO

LOAD TERMINAL

TERMINAL

TERMINAL

BARREL

TERMINAL

LOCATOR

WIRE

CONDUCTOR

ANVIL

Figure 3

CONDUCTOR

PUNCH

Operation

Refer to the instruction manual for the 19279-

0001 (AT-200) for mounting this crimp tool head.

Crimping Terminals

1.

Adjust the locator up or down until the

terminal being run sits flat and straight in the

tool.

2.

Insert the wire into the terminal. Push up on the locator blade and insert the terminal and wire into the proper

nest with the barrel up and against the locator bar. Release the locator blade to hold the terminal in position. See

Figure 1. Locator may be raised or lowered so terminal sits flat and straight in tool. The locator must be removed

to run splices.

Caution:

Never operate this tool without the supplied safety shield in place. Never place fingers in the tool nests.

3.

Push on the wire to assure it is fully seated in the terminal. See Figure 2 and 3. The

wires end should butt against the wire stop position of the locator. Cycle the tool.

4.

Lift the locator blade or wire stop and remove the crimped terminal. Inspect for proper

crimp location. Locator is adjustable up and down to keep terminals straight after

crimping.

5.

When crimping butt splices, the locator must be removed. Insert the wire into the butt

splice. Position the splice and the wire in proper coded nest with conductor crimp on the

conductor barrel of the splice The splice should be approximately centered inside the

tooling nests. See Figure 4. Cycle the tool.

Note

: Whenever crimping without the locator, make sure the seam

of the terminal is oriented up or down in the tool if using unbrazed

product, as this will provide higher pull force values.

6.

When crimping parallel splices, the locator must be removed.

Insert the 1

st

wire into one end of splice then insert the 2

nd

wire

into the opposite end of the parallel splice. This procedure will

crimp both wires at the same time. Make sure the wires are fully

seated into the parallel splice. Position the splice and the wires

in proper coded nest with conductor crimp on the conductor

barrel of the splice The splice should be approximately centered

inside the tooling nests. See Figure 5. Cycle the tool.

WIRE

TERMINAL

Figure 2

BUTT

SPLICE

VISUALLY

CENTER SPLICE

BARREL

CONDUCTOR

PUNCH

CONDUCTOR

ANVIL

Figure 4

WIRE

CONDUCTOR

ANVIL

Figure 5

VISUALLY

CENTER SPLICE

BARREL

PARALLEL

SPLICE

CONDUCTOR

PUNCH

2

ND

WIRE

1

ST

WIRE