Hand Crimp Tool for Pitch SPOX Crimp Terminals

Doc. No: 6382819HM

Release Date: 04-25-17

UNCONTROLLED COPY

Page 3 of 7

Revision: D

Revision Date: 01-08-19

WIRE

PUNCH

TERMINAL

WIRE STOP

BLADE

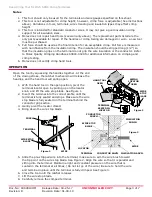

Figure 2

Figure 3

WIRE

INSULATION

PUNCH

WIRE STOP

BLADE

CONDUCTOR

PUNCH

LOCATOR

TERMINAL

INSULATION ANVIL

CONDUCTOR ANVIL

Notes

1.

This tool should only be used for the terminals and wire gauges specified on this sheet.

2.

This tool is not adjustable for crimp height; however, crimp force is adjustable (See instructions

above). Variations in tools, terminals, wire stranding and insulation types may affect crimp

height.

3.

This tool is intended for standard conductor sizes. It may not give a good insulation crimp

support for all insulation sizes.

4.

Molex does not repair hand tools (see warranty above). The replacement parts listed are the

only parts available for repair. If the handles or crimp tooling are damaged or worn, a new tool

must be purchased.

5.

Pull force should be used as the final criterion for an acceptable crimp. Pull force is measured

with no influence from the insulation crimp. The insulation should be stripped long (1/2”) so

that the insulation grips on the terminal do not grip the wire insulation or the conductor. Refer

to Molex Quality Crimping Handbook 63800-0029 for additional information on crimping and

crimp testing.

6.

Molex does not certify crimp hand tools.

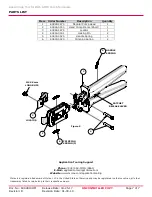

OPERATION

Open the tool by squeezing the handles together. At the end

of the closing stroke, the ratchet mechanism will release the

handles, and the hand tool will spring open.

1.

With the hand tool in the open position, pivot the

terminal locator open by pulling up on the locator

knob, and lift the wire stop blade. See Figure 1.

2.

Insert the terminal into the correct profile until the

terminal is fully seated and stops. Make sure the wire

stop blade is fully seated on the terminal behind the

conductor grip section.

3.

Gently pivot the locator closed.

4.

Bring down the wire stop blade.

5.

Slide the pre-stripped wire into the terminal; make sure to aim the wire brush toward

the tip point on the wire stop blade. See Figure 2. Align the wire so that it is parallel and

sitting into the terminal. Maintain a light and constant pressure on the wire that is

seated in the terminal at all times. (Do not let go of the wire.) Be sure to hold the wire

and terminal in place until the terminal is fully crimped. See Figure 3.

6.

Close the tool until the ratchet releases.

7.

Lift the wire stop blade.

8.

Carefully remove the crimped terminal.

TERMINAL

SEATED IN

LOCATOR

SWING

LOCATOR

OPEN

Figure 1

HAND TOOL

OPEN

WIRE

STOP

BLADE