01/08 AWB2190-1430GB

Setting the functions with DIP

switches/jumpers

79

Table 11: Indication of diagnostic status

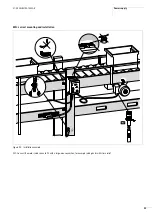

Set plug monitoring as part of Ready message

The motor plug monitoring message can also be assigned to Ready

message DI0 (

section “I/O assignment” on page 69).

This is recommended if

• the motor plug is used as isolating switch in combination with

lock shackle SET-M-LOCK (

• motors without temperature sensor winding are used and T1/T2

in the motor’s terminal board ae bridged (

a

figure 76 on page

73).

If maintenance work is performed under these conditions with

disconnected and locked motor plug, a Not Ready signal makes

more sense than a fault message.

To activate this operating mode, close the left hook jumper

(

a

table 12 on page 80).

In this opeating mode, a high-resistance connection between pins

5 and 8 of the motor plug (thermistor tripping or no motor plug)

the following effects:

• The motor switches off (as in the normal operating mode).

• No group error message is applied to DI1.

• LED Motor does not indicate a group error message.

• No Ready signal is applied to DI0, even if the key-switch is set

to AUTO.

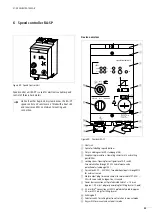

Setting the functions with DIP switches/jumpers

When the locking screw in the cover is undone, the electronics can

be configured through jumpers and DIP switches.

Diagnosic-

status

Status

group

errors

1

Peripheral error

(FID)

Explanation

P1

P2

P3

DI1

Contactor faulty

0

0

1

1

1

Contactor in On position without actuation signal

Overload trip

0

1

0

1

0

Trip from 110 % of thermal motor simulation value

Thermistor

tripping

0

1

1

1

0

Tripping through excessive resistance in thermistor sensor circuit

NO diagnostic

signal

1

1

1

1

0

Possible causes:

• Overload or short circuit of external inputs I3, I4

• Overload or short circuit of external output O3

• Incorrect DIP switch setting

• No 24 V supply voltage

• Tripping on drop below lower current threshold

Manual mode

1

0

0

0

0

Key-switch in MANUAL position

Load signal

1

0

1

0

0

Signal from 90 % of thermal motor simulation value

Load signal

1

1

0

0

0

Signal from 70 % of thermal motor simulation value

1) see I/O error message on page 75

h

Before you change the configuration and parameter

settings, make sure the key-switch is in its OFF position.

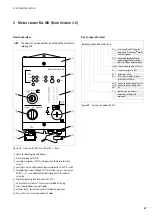

Figure 85: DIP switch/jumper

a

Jumper left, settings

a

table 12

b

Jumpers right

a

table 12

c

Information digit for service

d

DIP switches: 1 – 4 for setting current values

5 – 10 for setting additional functions

e

Jumper bottom,

a

table 12

1

1

0

OFF

2

3

4

5

1

ON

DIP

2

3

4

5

6

7

9 10

8

1

0

M

V

3

.7.1

a

b

d

e

c

Summary of Contents for Rapid Link

Page 10: ...01 08 AWB2190 1430GB 6 ...

Page 40: ...01 08 AWB2190 1430GB 36 ...

Page 48: ...01 08 AWB2190 1430GB 44 ...

Page 70: ...01 08 AWB2190 1430GB 66 ...

Page 146: ...01 08 AWB2190 1430GB 142 ...

Page 162: ...01 08 AWB2190 1430GB 158 ...