7

START-UP PROCEDURE

Pilot Flame Adjustment (Intermittent Pilot and

Millivolt Standing Pilot control systems – Control

Codes 04, 08, 27, and 67

The pilot burner is orificed to burn properly with an inlet

pressure of 7-14" W.C. on natural gas and 11-14" W.C. on

propane gas, but final adjustment must be made after

installation. If the pilot flame is too long or large, it is possible

that it may cause soot on the burner assembly. If the pilot flame

is shorter than shown, it may cause poor ignition and result in

the controls not opening the combination gas control. A dirty

pilot orifice may cause a short flame. Pilot flame condition

should be observed periodically to assure trouble-free

operation.

To adjust the pilot flame:

1. Create a call for heat from the thermostat.

2. Remove the cap from the pilot adjustment screw. For

location, see the combination gas control literature supplied

with unit.

3. Adjust the pilot flame length by turning the screw in or out

to achieve a soft steady flame 3/4" to 1" long and

encompassing 3/8"-1/2" of the tip of the flame sensing rod

or power-pile (See Figure 7.1).

4. Replace the cap from the pilot adjustment screw.

Main Burner Adjustment

The gas pressure regulator (integral to the combination gas

control) is adjusted at the factory for average gas conditions.

It is important that gas be supplied to the heater in accordance

with the input rating on the serial plate. Actual input should be

checked and necessary adjustments made after the heater is

installed. Over-firing, a result of too high an input, reduces the life

of the appliance and increases maintenance. Under no

circumstances should the input exceed that shown on the serial

plate.

Measuring the manifold pressure is done at the test port on the

main gas valve on the unit (See Figure 7.2).

To adjust the manifold pressure:

1. The correct manifold pressure is 6" W.C. for natural gas

and 10" W.C. for propane gas. Adjust the main gas

pressure regulator spring to achieve the proper manifold

pressure (see Figure 7.2).

2. Move the field installed manual shut-off valve to the “OFF”

position.

3. Remove the 1/8" pipe plug in the gas valve adjacent to the

manifold and attach a water manometer of “U” tube type

that is at least 12" high.

4. Move the field installed manual shut-off valve to the “ON”

position.

5. Create a call for heat from the thermostat.

6. After adjustment, move the field installed manual shut-off

valve to the “OFF” position and replace the 1/8" pipe plug.

7. After the plug is in place, move the field installed manual

shut-off valve to the “ON” position and recheck pipe plugs

for gas leaks with a soap solution.

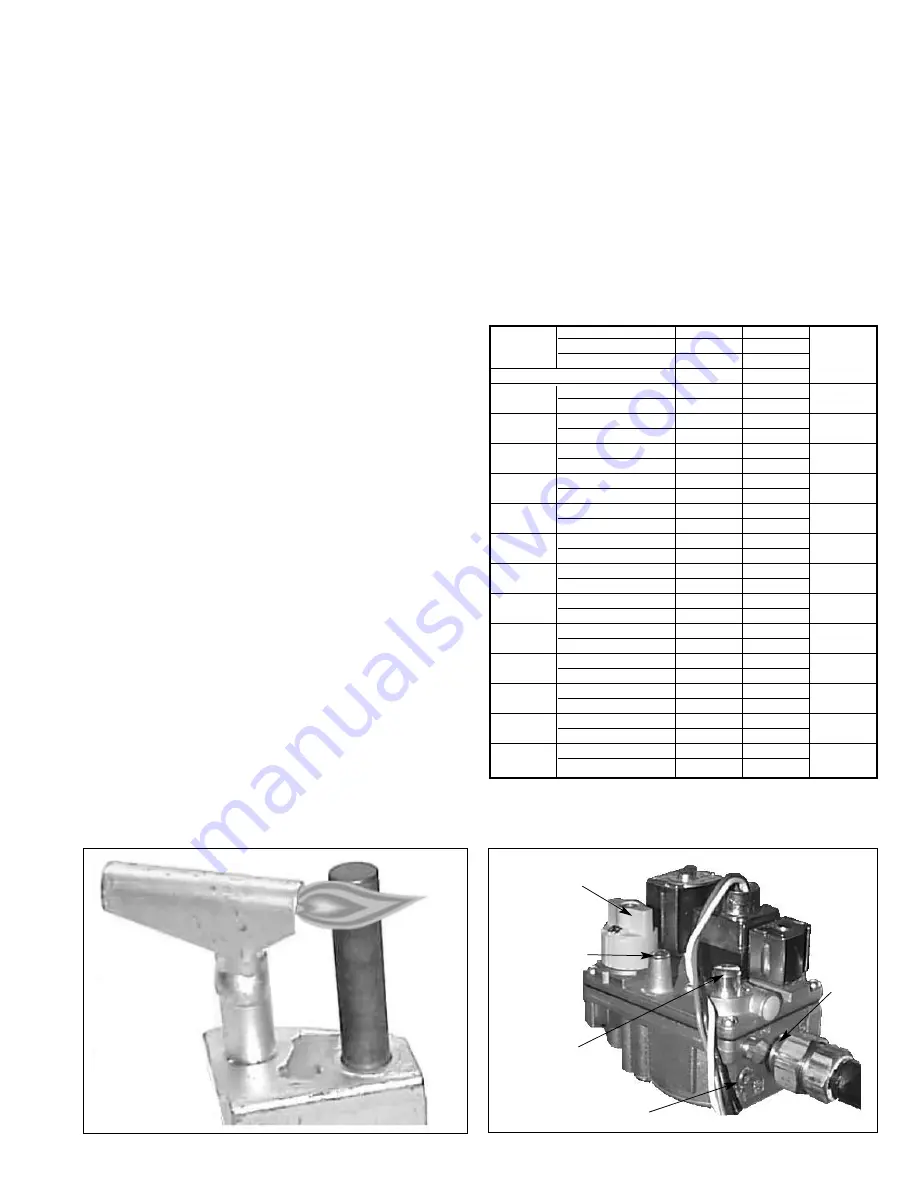

Figure 7.1

Correct Pilot Flame (Millivolt Powerpile shown)

Figure 7.2

Gas Valve Features

Pilot Adjustment

Screw (Under Cap)

Regulator Adjustment

Screw (Under Cap)

Plugged Outlet

Pressure Tap

Pilot Line

Connectio

n

Control

Knob

Type of Gas

Natural

Propane

Model

Btu/Ft.

3

1040

2500

No. of

Size

Specific Gravity

0.60

1.53

Orifices

Manifold Pressure In. W.C.

6.0

10

MT-28

cfh

26.4

-

1

Orifice Drill Size

#43

-

MT-30

cfh

28.8

12.0

1

Orifice Drill Size

#42

#52

MT-33

cfh

32.2

-

1

Orifice Drill Size

#41

-

MT-56

cfh

52.9

-

2

Orifice Drill Size

#43

-

MT-60

cfh

57.7

24.0

2

Orifice Drill Size

#42

#52

MT-66

cfh

64.4

-

2

Orifice Drill Size

#41

-

MT-84

cfh

79.3

-

3

Orifice Drill Size

#43

-

MT-90

cfh

86.5

36.0

3

Orifice Drill Size

#42

#52

MT-99

cfh

96.6

-

3

Orifice Drill Size

#41

-

MT-112

cfh

105.8

-

4

Orifice Drill Size

#43

-

MT-120

cfh

115.4

48.0

4

Orifice Drill Size

#42

#52

MT-132

cfh

128.8

-

4

Orifice Drill Size

#41

-

MT-160

cfh

153.8

64.0

4

Orifice Drill Size

#38

#49

Table 7.1

Manifold Pressure and Gas Consumption