28

Specifications are subject to change without notice.

© 2017 Mitsubishi Electric US, Inc.

7. Humidifier control

The below table shows how the field installed humidifier and fan speed is controlled.

A basic connection method is shown below.

1. Control specifications and DIP S/W setting

2. Installation

DIP switch

setting

Humidistat

output

Condition (no defrost/no error) CN25 output Fan speed

SW1 6

CNF input

OFF

OFF

Heat operation & Thermo OFF

OFF

RC setting

Heat operation & Thermo ON

ON

Heat operation & Thermo OFF OFF

RC setting

Heat operation & Thermo ON

ON

High

ON

OFF

Heat operation & Thermo OFF OFF

RC setting

Heat operation & Thermo ON

ON

Heat operation & Thermo OFF ON

High

Heat operation & Thermo ON

-

-

Except for heat operation

OFF

RC setting

RC:Remote controller

The fan continues to run for 30 seconds after the humidifier stops.

CNF

CN25

Humidistat

XA

SVA

Humidifier

XA

Indoor unit

control board

On-site preparation

Maximum cable length is 10m(32ft)

Humidifier

pow

er source

Use XA relay having following specifications

Rated voltage:12VDC

Power consumption:1W or less

Humidistat:Minimum applicable load 1mA at DC

Contact rating voltage:15VDC or more

Contact rating current:0.1A or more

7. Fan indication

The below table shows how the fan indication is controlled.

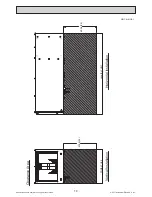

A basic connection method is shown below.

1. Indication specifications

2. Installation

Condition

Fan speed

CNEC2 output

Relay on the board

No. of CNEC2

Very low

X11

1

Low

X12

2

Middle

X13

3

High

X14

4

Indoor unit power board

XF1

XF2

XF3

XF4

COM

High

Middle

Low

Very low

1

2

3

4

5

On-site preparation

Maximum cable length is 10m(32ft)

XF1,2,3,4 power source: DC30V, 1A or less,

AC230V, 1A or less

X11

X12

X13

X14

CNEC2

1

2

3

4

5

Summary of Contents for PVFY-P12 NAMU-E

Page 2: ......