Smooth all around

Even length

all around

Inside is shining without any scratches.

Copper pipe

Good

No good

Tilted

Uneven

Burred

Burr

Copper pipe

Spare

reamer

Pipe

cutter

90

°

Remove two fi xing

screws to open the

service panel.

Service panel

Fixing screws

Be sure to put the left

portion into the square

hole of the service panel.

Be sure to fi x the indoor/outdoor unit

connecting wire

A

and power supply

cord

K

using this cord clamp.

Valve cover

WARNING

Be sure to attach the service panel of the outdoor unit securely. If it is not attached

correctly, it could result in a fi re or an electric shock due to dust, water, etc.

6. INDOOR/OUTDOOR UNIT CONNECTION

FINISHING AND TEST RUN

INSTALLATION INFORMATION FOR THE AIR CONDITION-

ER WITH R410A REFRIGERANT

•

This room air conditioner adopts an HFC refrigerant (R410A) which will never destroy

the ozone layer.

•

Pay particular attention to the following points, though the basic installation proce-

dure is same as that for R22 air conditioners.

1

As R410A has a working pressure approx. 1.6 times as high as that of R22, some

special tools and piping parts / materials are required. (Refer to the table below.)

2

Take suffi cient care not to allow water and other contaminations to enter the

R410A refrigerant during storage and installation, since it is more susceptible to

contaminations than R22.

3

For refrigerant piping, use clean, pressure-proof parts / materials specifi cally de-

signed for R410A. (Refer to 2. Refrigerant piping.)

4

Composition change may occur in R410A since it is a mixed refrigerant. When

charging, charge liquid refrigerant to prevent composition change.

6-1 Tools dedicated for the air conditioner with R410A

refrigerant

The following tools are required for R410A refrigerant. Some R22 tools can be substi-

tuted for R410A tools.

The diameter of the service port on the stop valve in outdoor unit has been changed to

prevent any other refrigerant being charged into the unit. (Cap size has been changed

from 7/16 UNF with 20 threads to 1/2 UNF with 20 threads.)

R410A tools

Can R22

tools be

used?

Description

Gauge manifold

No

R410A has high pressures beyond the measurement range

of existing gauges.

Port diameters have been changed to prevent any other

refrigerant from being charged into the unit.

Charge hose

No

Hose material and cap size have been changed to improve

the pressure resistance.

Gas leak detector

No

Dedicated for HFC refrigerant.

Torque wrench

Yes

1/4

No

1/2 and 5/8

Flare tool

Yes

Clamp bar hole has been enlarged to reinforce the spring

strength in the tool.

Flare gauge

New

Provided for fl aring work (to be used with R22 fl are tool).

Description

New

Provided to prevent the back fl ow of oil. This adapter

enables you to use existing vacuum pumps.

Electronic scale

for refrigerant

charging

New

It is diffi cult to measure R410A with a charging cylinder

because the refrigerant bubbles due to high pressure and

high-speed vaporization.

No: Not substitutable for R410A Yes: Substitutable for R410A

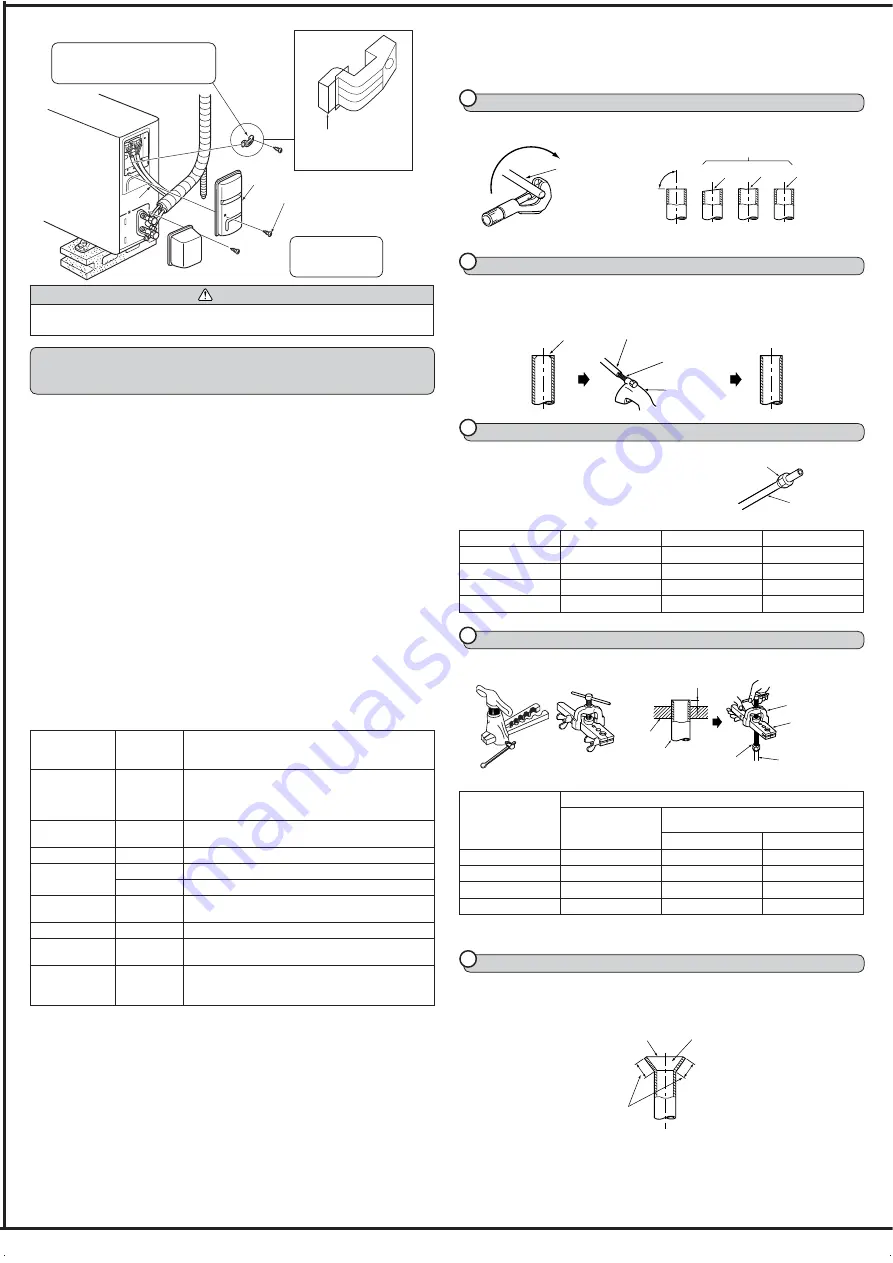

6-2 FLARING WORK

•

Main cause of gas leakage is defect in fl aring work.

Carry out correct fl aring work in the following procedure.

1 Pipe cutting

• Cut the copper pipe correctly with pipe cutter.

2 Burrs removal

• Completely remove all burrs from the cut cross section of pipe.

• Put the end of the copper pipe to downward direction as you remove burrs in order to

avoid to let burrs drop in the piping.

3 Putting nut on

• Remove

fl are nuts attached to indoor and outdoor

units, then put them on pipe having completed

burr removal.

(not possible to put them on after fl aring work)

• Flare nut for R410A pipe differs from R22 pipe.

Refer to the following table for detail.

mm

inch

R410A

R22

ø6.35

1/4

17

17

ø9.52

3/8

22

22

ø12.7

1/2

26

24

ø15.88

5/8

29

27

4 Flaring work

• Carry

out

fl aring work using fl aring tool as shown below.

Outside diameter

A (mm)

Flare tool for

R410A clutch type

Conventional fl are tool

Clutch type

Wing nut type

ø6.35 mm

0 to 0.5

1.0 to 1.5

1.5 to 2.0

ø9.52 mm

0 to 0.5

1.0 to 1.5

1.5 to 2.0

ø12.7 mm

0 to 0.5

1.0 to 1.5

2.0 to 2.5

ø15.88 mm

0 to 0.5

1.0 to 1.5

2.0 to 2.5

• Firmly hold copper pipe in a die in the dimension shown in the table above.

5 Check

• Compare

the

fl ared work with fi gure below.

• If

fl are is noted to be defective, cut off the fl ared section and do fl aring work again.

Flare nut

Copper pipe

A

Die

Copper pipe

Flare nut

Die

Copper pipe

York

Flaring tool

Wing nut type

Clutch type