EN

EN-12

7.4. Function settings

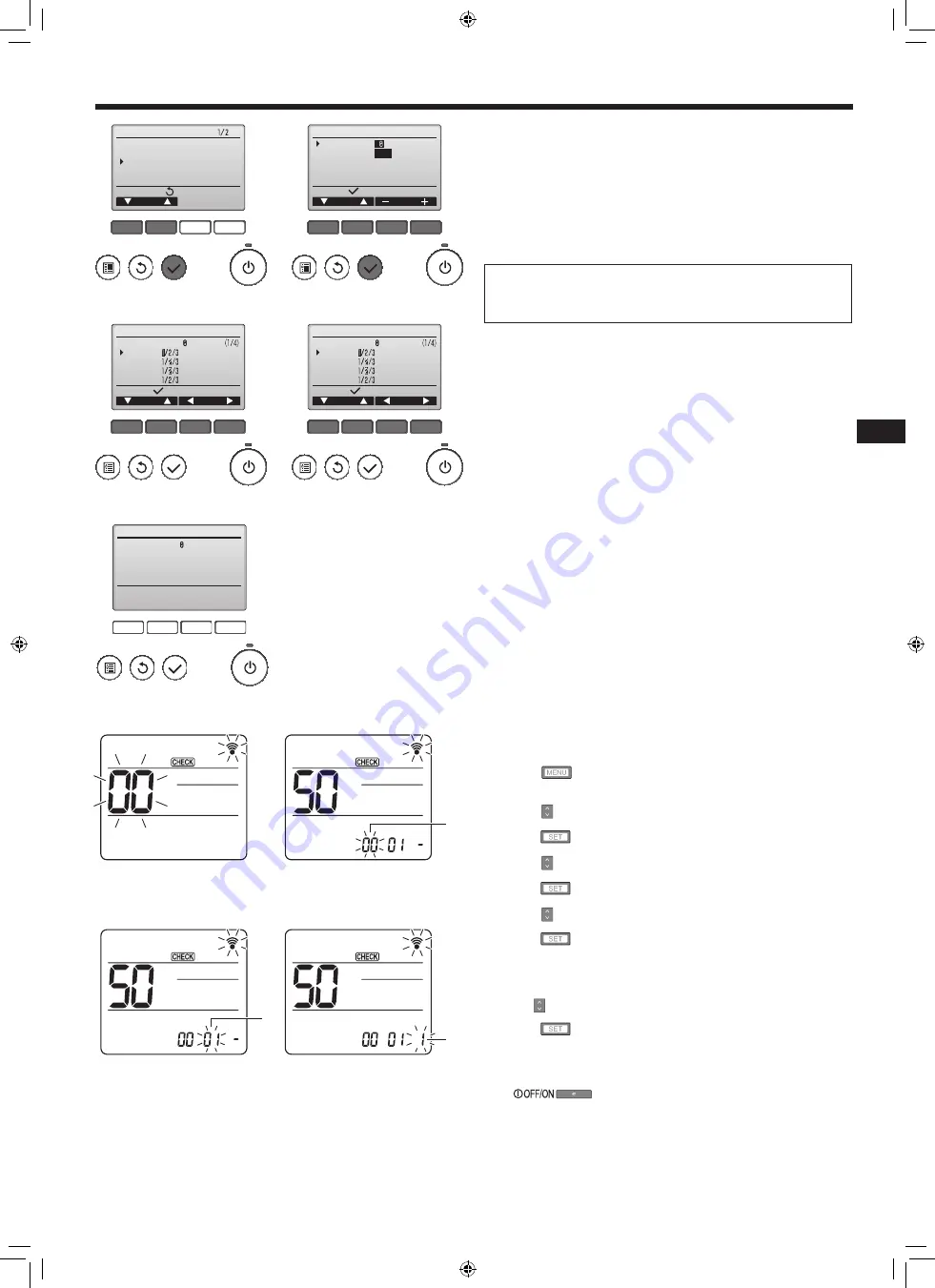

7.4.1. By wired remote controller

1

(Fig. 7-11)

•

Select “Service” from the Main menu, and press the [SELECT] button.

• Select “Function setting” with the [F1] or [F2] button, and press the [SELECT]

button.

2

(Fig. 7-12)

• Set the indoor unit refrigerant addresses and unit numbers with the

[F1]

through [F4] buttons, and then press the [SELECT]

button to confi rm the cur-

rent setting.

<Checking the Indoor unit No.>

When the

[SELECT] button is pressed, the target indoor unit will start fan opera-

tion. If the unit is common or when running all units, all indoor units for the se-

lected refrigerant address will start fan operation.

3

(Fig. 7-13)

• When data collection from the indoor units is completed, the current settings

appears highlighted. Non-highlighted items indicate that no function settings

are made. Screen appearance varies depending on the “Unit No.” setting.

4

(Fig. 7-14)

• Use the

[F1] or [F2] button to move the cursor to select the mode number, and

change the setting number with the [F3] or [F4] button.

5

(Fig. 7-15)

• When the settings are completed, press the

[SELECT] button to send the set-

ting data from the remote controller to the indoor units.

• When the transmission is successfully completed, the screen will return to the

Function setting screen.

7. Electrical work

F1

F2

F3

F4

Service menu

Cursor

Main menu:

Test run

Input maintenance info.

Function setting

Check

Self check

F1

F2

F3

F4

Function setting

Cursor

Address

Monitor:

Ref. address

Unit No.

Grp.

/1/2/3/4/All

Fig. 7-11

Fig. 7-13

Fig. 7-12

Fig. 7-14

F1

F2

F3

F4

Function setting

Cursor

Cursor

Request:

Ref. address

Mode 1

Mode 2

Mode 3

Mode 4

Grp.

F1

F2

F3

F4

Function setting

Cursor

Cursor

Request:

Ref. address

Mode 7

Mode 8

Mode 9

Mode 10

Unit # 1

Fig. 7-16

Fig. 7-18

Fig. 7-17

Fig. 7-19

F1

F2

F3

F4

Function setting

Ref. address

Sending data

Fig. 7-15

7.4.2. By wireless remote controller (Fig. 7-16, Fig. 7-17, Fig. 7-18, Fig.

7-19)

1

Going to the function select mode

Press the

button between of 5 seconds.

(Start this operation from the status of remote controller display turned off.)

[CHECK] is lighted and "00" blinks. (Fig. 7-16)

Press the

button to set the "50".

Direct the wireless remote controller toward the receiver of the indoor unit and

press the

button.

2

Setting the unit number

Press the

button to set unit number

A

. (Fig. 7-17)

Direct the wireless remote controller toward the receiver of the indoor unit and

press the

button.

3

Select a mode

Press the

button to set Mode number

B

. (Fig. 7-18)

Direct the wireless remote controller toward the receiver of the indoor unit and

press the

button.

Current setting number:

1=1 beep (1 second)

2=2 beep (1 second each)

3=3 beep (1 second each)

4

Selecting the setting number

Use the

button to change the Setting number

C

. (Fig. 7-19)

Direct the wireless remote controller toward the receiver of the indoor unit and

press the

button.

5

To select multiple functions continuously

Repeat select

3

and

4

to change multiple function settings continuously.

6

Complete function selection

Direct the wireless remote controller toward the sensor of the indoor unit and press

the

button.

Note:

Make the above settings on Mr. Slim units as necessary.

• Table 1 summarizes the setting options for each mode number.

• Be sure to write down the settings for all functions if any of the initial settings

has been changed after the completion of installation work.

A

B

C

BH79A367W01_01En.indd 12

2018/05/30 9:17:47