5. BUS CONNECTION

5.4 Precautions

5 - 37

1

P

R

EP

ARA

T

OR

Y

P

R

OCEDURES

FOR

MONIT

O

R

ING

2

D

E

VICE RA

NGE

T

H

A

T

CAN

B

E

SET

3

ACCESS

RA

N

G

E

F

O

R MONIT

O

R

ING

4

HOW T

O

MONIT

O

R

REDUNT

ANT

SYS

TEM

5

BUS CONNECTION

6

DIR

E

CT

CONNECTION T

O

CPU

7

COMP

UT

E

R

L

INK

CONNE

C

T

ION

8

E

T

HE

RN

E

T

CONN

E

C

T

ION

5.4.3

Powering OFF the GOT,

reapplying the power (OFF to

ON)

(1) Precautions for reapplying the power to the GOT

(OFF to ON)

Do not power-cycle the GOT (OFF to ON) while the

PLC is ON.

Before doing so, be sure to turn off the PLC first.

HINT

HINT

HINT

Operations causing automatic reboot of the GOT1000

Series

Since the GOT1000 Series is automatically rebooted

in the following cases, the power does not need to be

reapplied to the GOT (OFF to ON).

• When an OS is written from GT Designer3 or a CF

card

• When utility settings have been changed

(2) When turning OFF the GOT before display of the

user creation screen

When the GOT is turned OFF before the user creation

screen is displayed on the GOT, subsequent

communications may be no longer possible.

In such a case, reapply the power to the PLC CPU and

GOT.

(3) Precautions for connection of 3 GOTs or more (when

connecting QCPU (Q mode))

5.4.10 (1)Restrictions in overall cable length to

No. of GOTs

5.4.4

Reset switch on GOT

When bus connection is used, the reset switch on the GOT

does not function.

5.4.5

Powering OFF or resetting the

PLC

(1) When turning OFF or resetting the PLC during

monitoring

When turning OFF or resetting the PLC during

monitoring, the system alarm (No.402: timeout error) is

generated.

When the PLC CPU is restored, the GOT automatically

resumes monitoring.

Use System Information to reset the alarm.

For the System Information, refer to the following

manual:

GT Designer3 Version Screen Design

Manual

(2) When turning OFF or resetting the PLC CPU before

display of the user creation screen

When the PLC CPU is turned OFF or reset before the

user creation screen is displayed on the GOT,

subsequent communications may be no longer

possible.

In such a case, reapply the power to the PLC CPU and

GOT.

(3) Precautions for connection of 3 GOTs or more (when

connecting QCPU (Q mode))

5.4.10 (1)Restrictions in overall cable length to

No. of GOTs

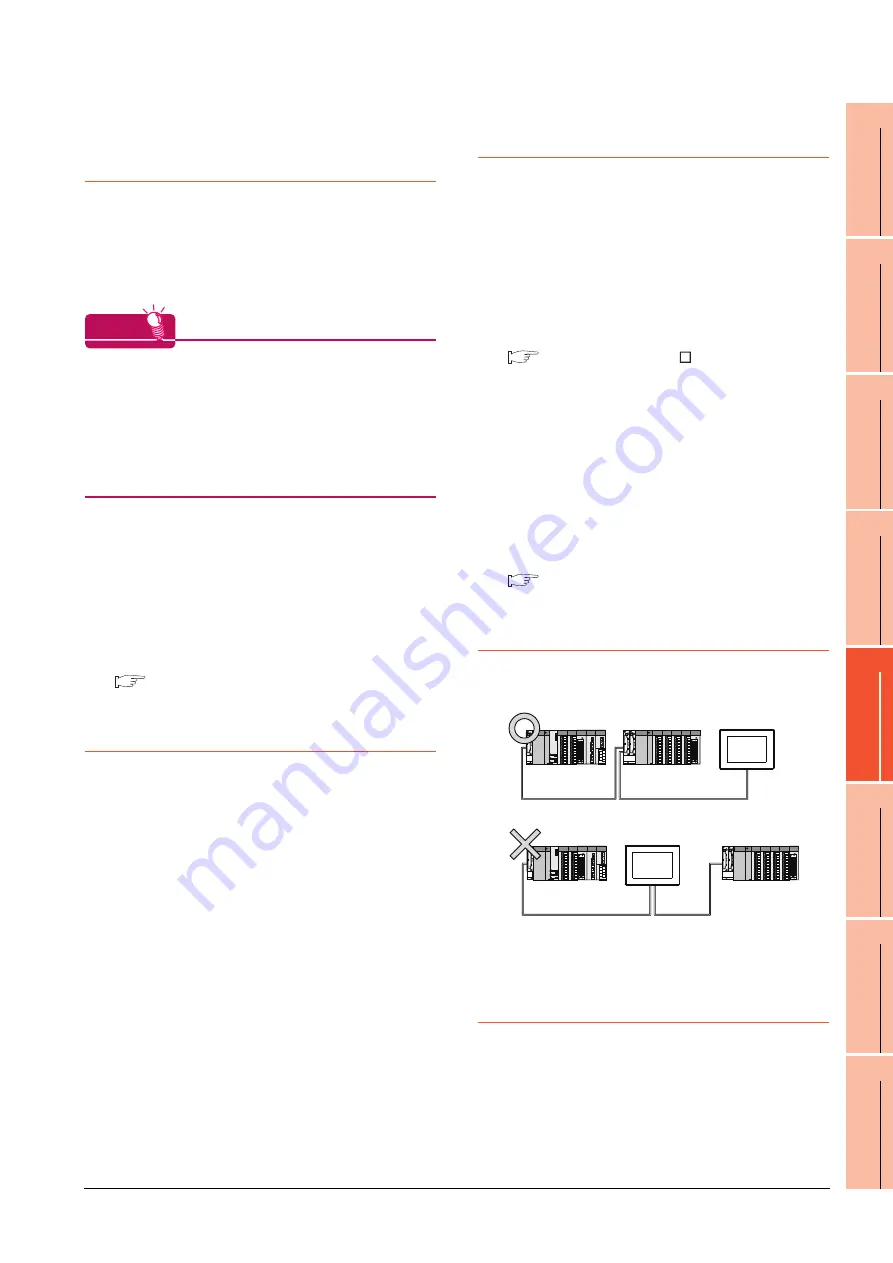

5.4.6

Position of the GOT

Always connect the GOT to the last base unit.

Connecting a GOT between base units is not allowed.

5.4.7

When the GOT is bus-

connected to a PLC CPU

without the communication

driver written

When the GOT is bus-connected to a PLC CPU without the

standard monitor OS and the communication driver for the

bus connection being written onto the GOT, the PLC CPU

is reset. (GX Developer cannot communicate with the PLC

CPU)

In this case, disconnecting the bus connection cable from

the GOT will cancel the reset status of the PLC CPU.

Summary of Contents for GT15

Page 2: ......

Page 34: ...A 32 ...

Page 92: ......

Page 110: ...2 18 2 DEVICE RANGE THAT CAN BE SET 2 9 MELSEC WS ...

Page 186: ...5 10 5 BUS CONNECTION 5 2 System Configuration ...

Page 218: ...5 42 5 BUS CONNECTION 5 4 Precautions ...

Page 254: ...6 36 6 DIRECT CONNECTION TO CPU 6 6 Precautions ...

Page 286: ...7 32 7 COMPUTER LINK CONNECTION 7 6 Precautions ...

Page 350: ...8 64 8 ETHERNET CONNECTION 8 5 Precautions ...

Page 368: ...9 18 9 MELSECNET H CONNECTION PLC TO PLC NETWORK 9 5 Precautions ...

Page 420: ...11 26 11 CC Link IE CONTROLLER NETWORK CONNECTION 11 5 Precautions ...

Page 440: ...12 20 12 CC Link IE FIELD NETWORK CONNECTION 12 5 Precautions ...

Page 490: ...13 50 13 CC Link CONNECTION INTELLIGENT DEVICE STATION 13 5 Precautions ...

Page 510: ......

Page 564: ...15 54 15 INVERTER CONNECTION 15 7 Precautions ...

Page 668: ......

Page 712: ...21 12 21 MULTIPLE GT14 GT12 GT11 GT10 CONNECTION FUNCTION 21 5 Precautions ...

Page 713: ...MULTI CHANNEL FUNCTION 22 MULTI CHANNEL FUNCTION 22 1 ...

Page 714: ......

Page 760: ...22 46 22 MULTI CHANNEL FUNCTION 22 5 Multi channel Function Check Sheet ...

Page 761: ...FA TRANSPARENT FUNCTION 23 FA TRANSPARENT FUNCTION 23 1 ...

Page 762: ......

Page 860: ...REVISIONS 4 ...

Page 863: ......