4.4 System Parameters

200

℃

300

℃

360

seconds

10

10V

0

℃,

1 is

℉

is

100

℃~

400

℃

100

℃~

400

℃

60

~

9999

seconds

300

~

9999

seconds

5

-

25

9

-

12V

Notice: Preset parameter(s) will be updated to TS100 after saved.

180

seconds

℃

13

4

O p e r a t i o n

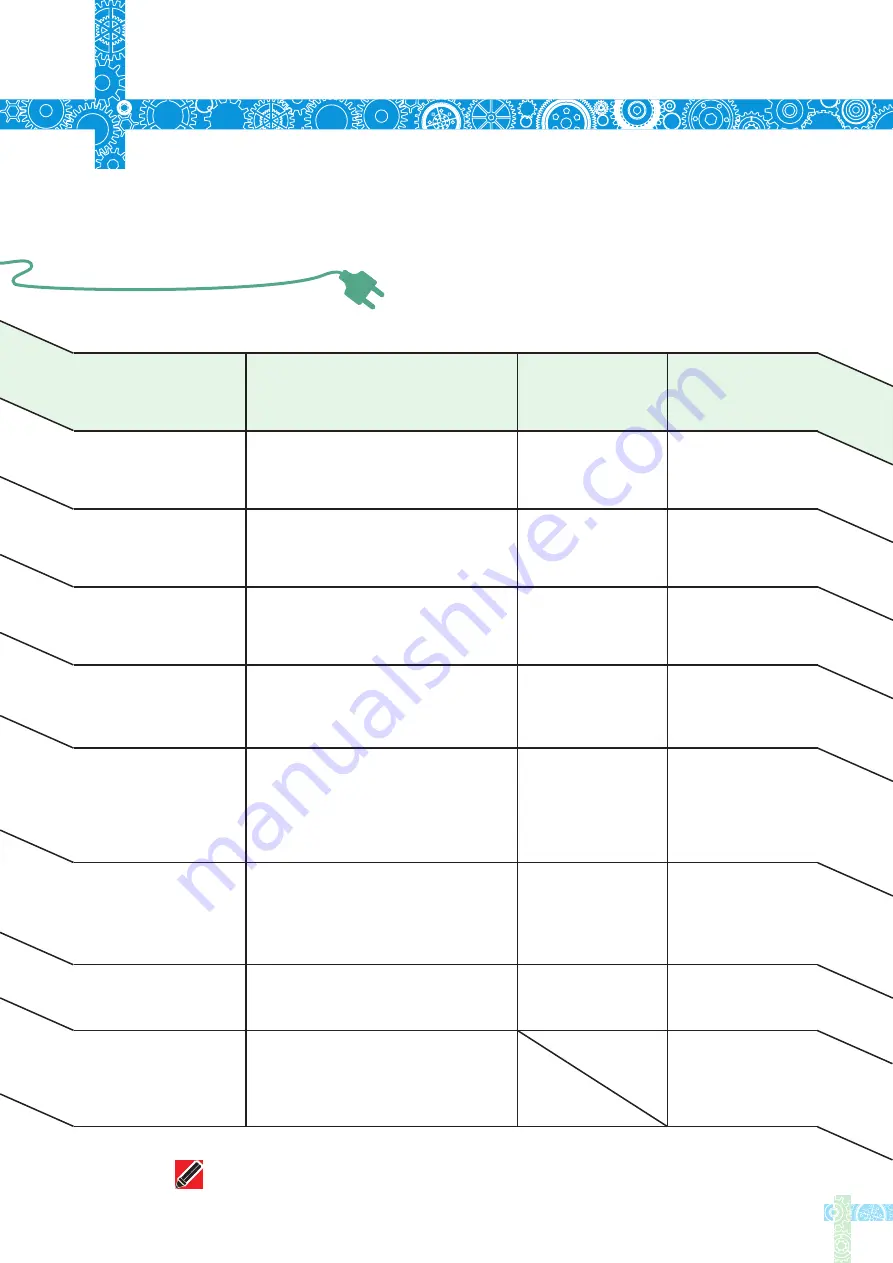

Parameter

Explanation

Default

Adjustable

range

T_Standby

T_Work

Wait_Time

Idle_Time

T_Step

Turn_Off_v

TempShowFlag

ZeroP_Ad

Standby mode temerature

Operating temperature

Time from operation mode

to sleep mode

Time from sleep mode

to standby mode

When preset "1",each step

will progress in 1,2,5,25;

when preset 2-25, each step

will progress according to

settings

When operation voltage is

lower than default voltage

TS100 will return to stadby

mode

Temperature unit selection

Temperature calibration

parameter, TS100 automatical

adjustment

No manual

setting required