Forward Speed (FWD SPEED):

The FWD SPEED se�ng determines the actuator speed in the forward

direc�on (when A1 is posi�ve with respect to A2). Turning the trim pot clockwise increases forward

motor speed.

Reverse Speed (REV SPEED):

The REV SPEED se�ng determines the actuator speed in the reverse

direc�on (when A2 is posi�ve with respect to A1). Turning the trim pot clockwise increases reverse

motor speed.

Motor Torque (MOTOR CL):

The MOTOR CL sets the maximum amount of current the actuator can

draw when accelera�ng (motoring) the actuator in either direc�on. To calibrate the MOTOR CL:

1. With the power disconnected from the drive, connect a DC ammeter in series with the

1.

actuator.

2. Set the MOTOR CL trim pot to minimum (full CCW).

3. Command minimum posi�on (posi�on poten�ometer full CCW or analog signal at 0 VDC).

4. Carefully lock the actuator. Be sure that it is is firmly mounted.

5. Apply power source and command the actuator to move. The actuator should be stopped.

6. Slowly adjust the MOTOR CL trim pot CW un�l the actuator current is 150% of rated current.

7. Command minimum posi�on (posi�on poten�ometer full CCW or analog signal at 0 VDC).

8. Remove power source.

9. Remove the stall from the actuator.

10. Remove the ammeter in series with the actuator if it is no longer needed.

Regen Torque (REGEN CL):

The REGEN CL sets the maximum amount of current the actuator can draw

when stopping in either direc�on. If the red LED comes on when stopping, turn this trim pot clockwise

to increase the current limit.

Posi�onal Error (DEADBAND):

The DEADBAND trim pot sets the allowed error around the desired final

posi�on. Turning the trim pot clockwise allows for more error. If the DEADBAND is too low, the

actuator will oscillate at the commanded posi�on. If too high, the final posi�on may not be accurate

enough for the applica�on.

Error Gain (ERROR GAIN):

The ERROR GAIN trim pot sets the responsiveness of the control. Too li�le

ERROR GAIN and the system may seem sluggish. Too much ERROR GAIN and the actuator may

overshoot the target / oscillate.

Feedback Gain (FB GAIN):

The FB GAIN determines the fully extended posi�on. Turn the trim pot CW

to increase the extended posi�on. The FB GAIN and FB OFFSET interact with each other, so double

check the retracted posi�on (FB OFFSET) a�er adjus�ng the FB GAIN.

Feedback Offset (FB OFFSET):

The FB OFFSET determines the fully retracted posi�on. Turn the trim pot

CW to increase the retracted posi�on. The FB GAIN and FB OFFSET interact with each other, so double

check the extended posi�on (FB GAIN) a�er adjus�ng the FB OFFSET.

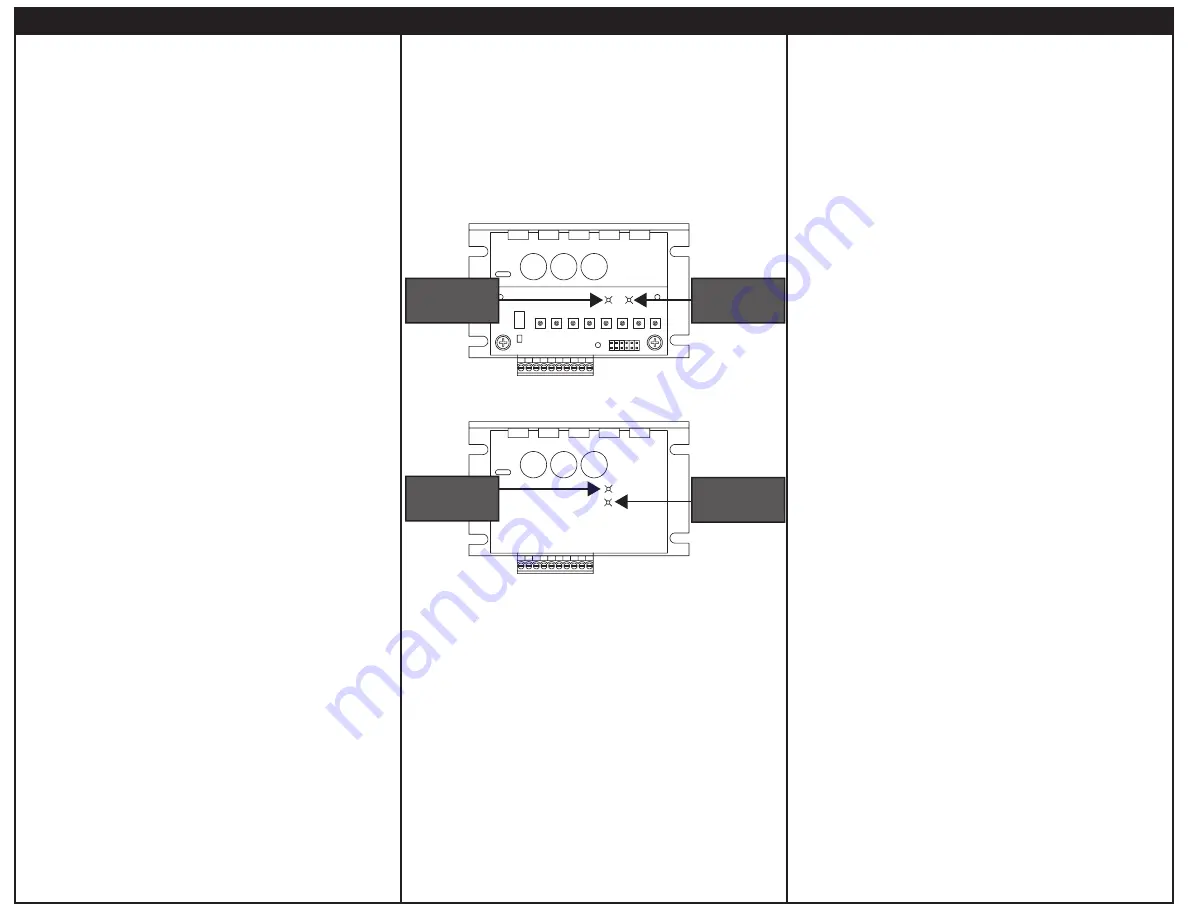

Calibration

A1

MOTOR

Green Status

LED

Red Status

LED

BOTTOM BOARD

MOTOR

CL

REGEN

CL

FWD

SPEED

REV

SPEED

FB

OFFSET

FB

GAIN

BAND

DEAD

ERROR

GAIN

A1

MOTOR

POWER

CUR LMT

Curr

en

t Limit

LED

P

o

wer LED

TOP BOARD

Current Limit (CURR LIMIT):

Red LED turns on whenever the drive reaches current limit.

Power (POWER):

Green LED turns on whenever DC source voltage is applied to the drive.

Status LEDs

- Over Voltage: Green and red LEDs flash quickly.

Status LEDs

- Over Voltage: The source voltage is too high (greater than 32 VDC).

Status LEDs

-

Under Voltage: Green LED flashes slowly. Motor output is disabled.

Status LEDs

-

Under Voltage: The source voltage is too low (less than 7.5 VDC).

Status LEDs

-

Over Temperature: Green LED flashes quickly. Motor output is disabled.

Status LEDs

-

Over Temperature: The ambient temperature is too high (greater than 55°C).

Status LEDs

-

Thermal Foldback: Red LED flashes quickly. Ambient temperature reached 75°C. Drive

Status LEDs

- Thermal Foldback:

will lower current limit un�l the ambient temperature lowers to

Status LEDs

- Thermal Foldback:

an acceptable opera�ng temperature.

BOTTOM BOARD LEDS

TOP BOARD LEDS

LEDs

- Verify that no foreign conduc�ve material is present on the printed circuit board.

1. If using a speed adjust poten�ometer, turn it fully counterclockwise (CCW). If using an analog signal,

1.

set it for 0 VDC.

2. Apply the DC source voltage.

3. Close the Enable switch.

4. Command a posi�on using the posi�on poten�ometer or analog signal. The motor should move to

4.

the commanded posi�on.

5. Remove the DC source voltage.

STARTUP

Startup

250-0460 rev 2

Copyright 2019 by American Control Electronics® - All rights reserved. No part of this document may

be reproduced or retransmi�ed in any form without wri�en permission from American Control

Electronics®. The informa�on and technical data in this document are subject to change without

no�ce. American Control Electronics® makes no warranty of any kind with respect to this material,

including, but not limited to, the implied warran�es of its merchantability and fitness for a given

purpose. American Control Electronics® assumes no responsibility for any errors that may appear in

this document and makes no commitment to update or to keep current the informa�on in this

document.