6

4. Periodically care (Once a week)

Users are advised to perform the maintenance works described below once a week so that the printer will

keep its high performance and accuracy over an extended period of its life.

(1) Platen (“Cleaning the Platen” Chapter 4 of the Operation Manual)

Platen is a place where dusts, paper powder, and ink are lia-

ble to accumulate. It is therefore suggested to clean it fre-

quently. Wipe out the platen surface and the platen cover

with a soft blush or cloth. The grooves for media holder and

for cutting the paper (cutter line) are the place where the

dusts are especially liable to accumulate. Clean them thor-

oughly.

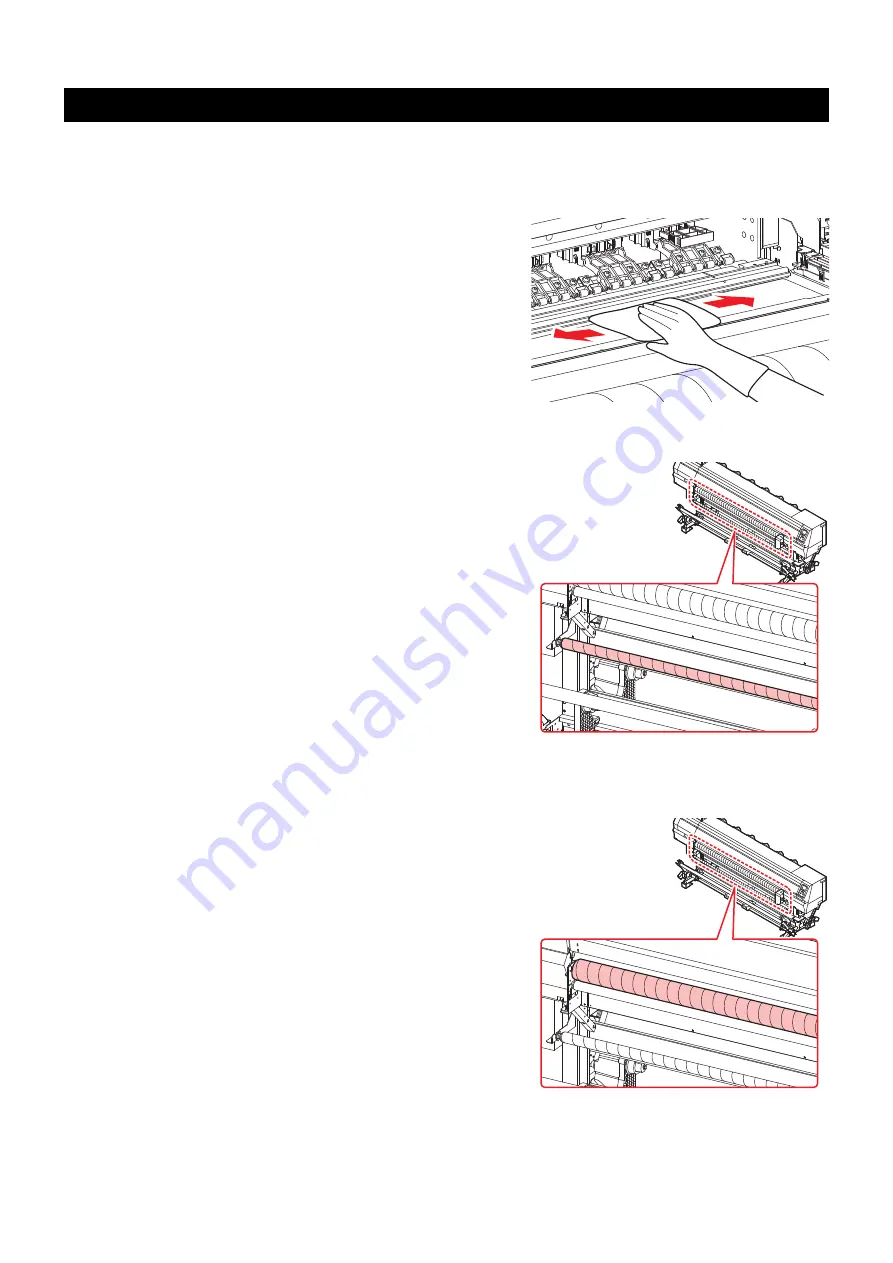

(2) Lapal bar (“Cleaning lapal bar (take-up side)” Chapter 4 of the Operation Manual)

Remove ink blot etc. adhering to the lapal bar located on the

front surface of the machine and used at takingup the media.

Moisten soft cloth with water or waterish mild detergent,

squeeze tightly and then wipe it off.

(3) Tension roller (“Cleaning the tension roller” Chapter 4 of the Operation Manual)

Remove ink stain etc. adhering to the tension roller at the

front side of the machine.

Moisten soft cloth with water or waterish mild detergent,

squeeze tightly and then wipe it off.