21

*

Data clear [DATA CLEAR]

The device terminates cutting of the current data, and starts cutting of new data.

If you want to stop cutting of the current data before the device completes it, you have to clear the data received.

• After the execution of data clear, the received data will remain in the receiver buffer.

It is, therefore, possible to cut (plot) the data in repetition using the plural sheet

cutting function.

Execute the data clear and set the device in the remote mode. When the device receives new data from the host computer, it will

cut the new data.

*

Change-over of cut mode [CUT MODE]

When smooth curve or fine finish is desired, this function is used to specify the cutting quality.

• Setting value (Make a choice and input it)

QUALITY*1

:

The device conducts cutting giving priority to the cutting quality.

NORMAL

:

The device conducts cutting normally.

HIGHspd*2

:

The device conducts cutting quickly.

*

Cutting up to the edge of a sheet. [EXPAND]

When cutting is to be made up to the edge of a sheet, the use of EXPAND function will enable plotting over the pinch roller.

Thus maximum plotting width can be expanded. While inside of the pinch roller is the normal plotting area, expansion of 10 mm

per side, total 20 mm, is possible.

• Setting value (Entering of choice.)

ON: Maximum plotting width is expanded.

OFF: Maximum plotting width is not expanded.

• When EXPAND is selected, dummy cut function for blade orientation adjustment cannot be

used. In order to adjust blade orientation prior to cutting, make test cutting "test cut

[square]".

• Preset value will be effective after sheet detection.

• Footprint by pinch roller and grid roller will remain.

*

Rotation [ROTATION]

This function is used to specify the location of origin and direction of the axis of coordinates according to the application

software to be used. After the sheet detection, Carriage will stop at the origin point on either the left edge or the right edge,

depending on the preset value.

• Setting value (Make a choice and input it)

ON

: The device rotates the coordinate axis and relocates the origin at a time.

OFF

: The device does not perform rotation of the coordinate axis.

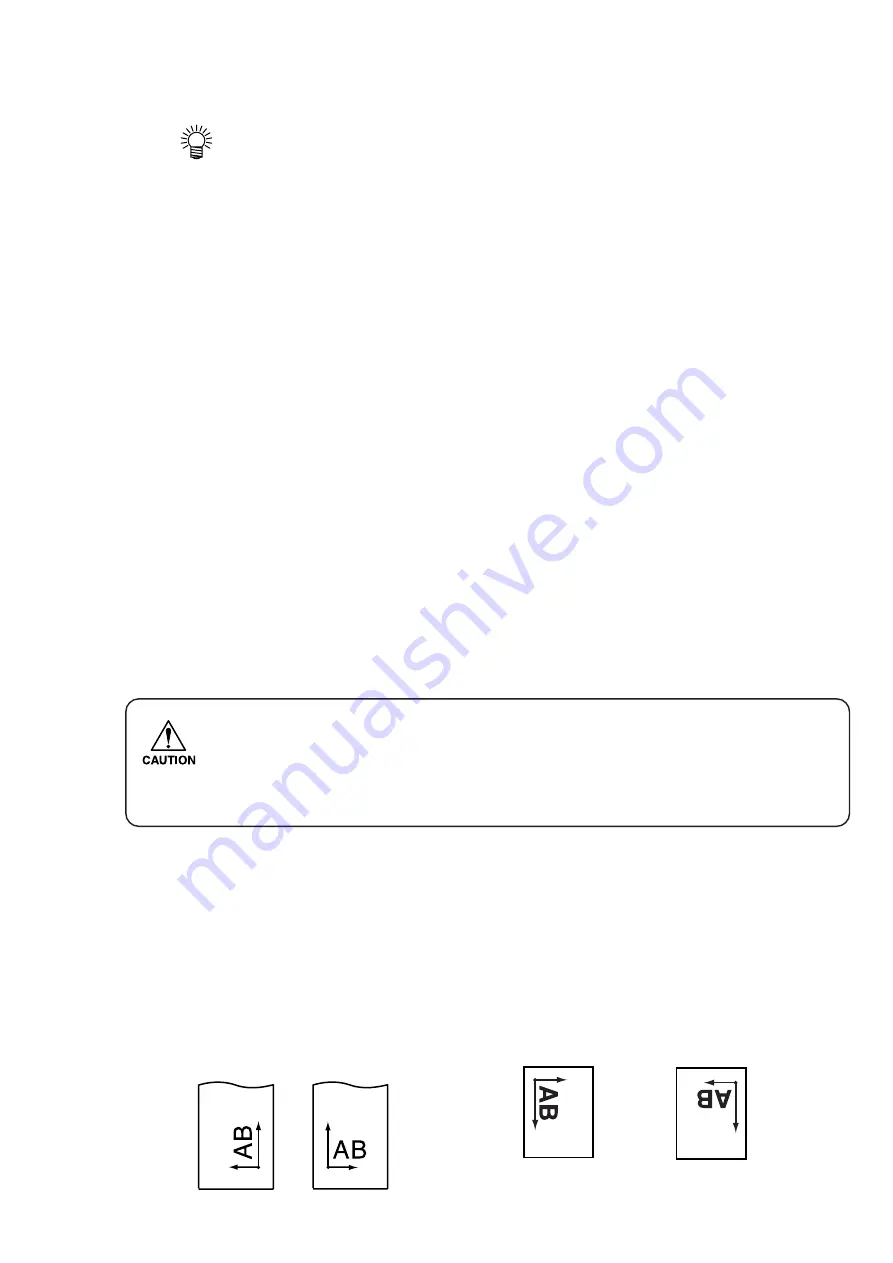

The device has four different axis of coordinates according to how the sheet loading direction and the angle of rotation of the

coordinate axis determined by the rotating function are combined.

Origin

Rotating function: OFF

Origin

The sheet is loaded on

the front of the device.

Rotation: OFF

The sheet is loaded on

the front of the device.

Rotation: ON

A(X)

B(Y)

Origin

A(Y)

B(X)

Origin

Rotating function: ON

*1: Select the “QUALITY” in the following cases:

• Where a character of which size is 10 mm or less

is to be cut

• Where a picture pattern or character that have

many sharp curves is to be cut

• Where fine cutting is to be performed

*2: It should be noted, however, that a pattern with a

rugged edges may be finished in the case where the

data sent from the host computer is excessively minute.

It is recommended in such a case to select the

“HIGHspd” for smoother finish.