13

12

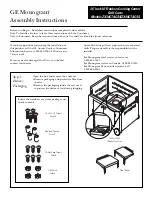

Replacing Brushes (Fig. 15 & 16)

MILWAUKEE

Magnum Drills have an ex-

clusive Brush Cartridge System. The tool

will not start when the brushes are worn

to 1/8", preventing expensive damage to

the armature. New brushes are provided

in the Cartridge for fast changes any-

where.

Brush holder

s c r e w

Brushes

Extra brushes

Brush

holder

Replacement screw

Fig. 15

Fig. 16

To reduce the chance of bit binding:

•

Use sharp bits. Sharp bits are less likely

to bind when drilling.

•

Use the proper bit for the job. There are

bits that are designed for specific pur-

poses.

•

Use caution when drilling pitchy, knotty,

wet or warped material or when drill-

ing in material that may contain nails.

Fig. 12

Forward rotation

Reaction

Bracing against the floor

Fig. 13

Forward

rotation

Bracing against your leg

Reaction

Bracing against a stud

Fig. 14

Reverse rotation

Reaction

Forward rotation

1.

Unplug tool and rest it on its side with

the cartridge facing up. Loosen the

brush holder screw in the cartridge and

pull cartridge out.

2.

Remove worn brushes. If the brushes

should fall into the tool, be sure to shake

them out before reinserting the car-

tridge. Discard

BOTH

brushes. Brushes

should always be replaced in sets.

3.

A set of spare brushes is provided in

the cartridge. Remove the brushes from

storage compartment.

4.

Position new brushes with the flat sil-

ver end facing into the brush holder.

Push cartridge into the tool and press

evenly on top and bottom of the car-

tridge to align terminals for proper con-

nection.

5.

Tighten the brush holder screw gently.

If the head of Screw is damaged, use

the replacement screw provided in the

cartridge.

Never use a metal screw as a

brush holder screw.

WARNING!

WARNING!

To reduce the risk of injury,

always unplug your tool before

performing any maintenance.

Never disassemble the tool or try

to do any rewiring on the tool's

electrical system. Contact a

MILWAUKEE service facility for

ALL repairs.

MAINTENANCE

Maintaining Tools

Keep your tool in good repair by adopting a

regular maintenance program. Before use,

examine the general condition of your tool.

Inspect guards, switches, tool cord set and

extension cord for damage. Check for

loose screws, misalignment, binding of

moving parts, improper mounting, broken

parts and any other condition that may af-

fect its safe operation. If abnormal noise

or vibration occurs, turn the tool off imme-

diately and have the problem corrected

WARNING!

To reduce the risk of injury,

electric shock and damage to the

tool, never immerse your tool in

liquid or allow a liquid to flow

inside the tool.

before further use. Do not use a damaged

tool. Tag damaged tools “DO NOT USE” until

repaired (see “Repairs”).

Under normal conditions, relubrication is

not necessary until the motor brushes

need to be replaced. After six months to

one year, depending on use, return your

tool to the nearest

MILWAUKEE

service

facility for the following:

•

Lubrication

•

Brush inspection and replacement

•

Mechanical inspection and cleaning

(gears, spindles, bearings, housing,

etc.)

•

Electrical inspection (switch, cord,

armature, etc.)

•

Testing to assure proper mechanical

and electrical operation

Cleaning

Clean dust and debris from vents. Keep

the tool handles clean, dry and free of oil

or grease. Use only mild soap and a damp

cloth to clean your tool since certain clean-

ing agents and solvents are harmful to plas-

tics and other insulated parts. Some of

these include: gasoline, turpentine, lacquer

thinner, paint thinner, chlorinated cleaning

solvents, ammonia and household deter-

gents containing ammonia. Never use flam-

mable or combustible solvents around

tools.

Repairs

If your tool is damaged, return the entire

tool to the nearest service center.

Bit Binding

A high rotational force occurs when a bit

binds. If the bit binds, the tool will be forced

in the opposite direction of the bit rotation

(See Fig. 12 - 14). Bits may bind if they are

misaligned or when they are breaking

through a hole. Wood boring bits can also

bind if they run into nails or knots. Be pre-

pared for bit binding situations.

Typical Bracing Methods