OM-2243 Page 25

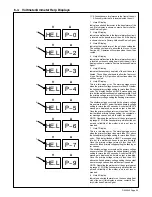

6-3. Voltmeter/Ammeter Help Displays

All directions are in reference to the front of the unit.

All circuitry referred to is located inside the unit.

1

Help 0 Display

Indicates a shorted thermistor in the transformer of the

unit. If this display is shown, contact a Factory Autho-

rized Service Agent.

2

Help 2 Display

Indicates a malfunction in the thermal protection circuit-

ry located on the transformer of the unit. If this display

is shown, contact a Factory Authorized Service Agent.

3

Help 3 Display

Indicates the transformer of the unit has overheated.

The unit has shut down to allow the fan to cool it (see

Section 4-2). Operation will continue when the unit has

cooled.

4

Help 4 Display

Indicates a malfunction in the thermal protection circuit-

ry located on the secondary heat sink of the unit. If this

display is shown, contact a Factory Authorized Service

Agent.

5

Help 5 Display

Indicates the secondary heat sink of the unit has over-

heated. The unit has shut down to allow the fan to cool

it (see Section 4-2). Operation will continue when the

unit has cooled.

6

Help 6 Display

This is a two-stage error. The warning stage occurs

when the primary voltage drops more than 12% below

the linked primary voltage setting for more than 30 sec-

onds. The display flashes a HELP 6 message during

idle, but the welder continues to operate normally. Once

the primary voltage returns to less than 10% below the

linked primary voltage setting the flashing error ceases.

The shutdown stage occurs when the primary voltage

drops more than 20% below the linked primary voltage

setting for more than 30 seconds. A constant HELP 6

message is displayed, and weld output is disabled.

Once the primary voltage returns to less than 10% be-

low the linked primary voltage setting, the constant er-

ror message ceases, and weld output is enabled.

NOTE: Operating the welder out of the normal operat-

ing range (

±

12% of the linked primary) will affect the out-

put and reliability of the welder, and is not recom-

mended.

7

Help 7 Display

This is a two-stage error. The warning stage occurs

when the primary voltage rises more than 12% above

the linked primary voltage setting for more than 30 sec-

onds. The display flashes a HELP 7 message during

idle, but the welder continues to operate normally.

Once the primary voltage returns to less than 10%

above the linked primary voltage setting the flashing er-

ror ceases.

The shutdown stage occurs when the primary voltage

rises more than 20% above the linked primary voltage

setting for more than 30 seconds. A constant HELP 7

message is displayed, and weld output is disabled.

Once the primary voltage returns to less than 10%

above the linked primary voltage setting the constant

error message ceases, and weld output is enabled.

NOTE: Operating the welder out of the normal operat-

ing range (

±

12% of the linked primary) will affect the out-

put and reliability of the welder, and is not recom-

mended.

8

Help 9 Display

Indicates a shorted thermistor on the secondary heat

sink of the unit. If this display is shown, contact a Fac-

tory Authorized Service Agent.

2

A

V

3

A

V

HE.L P

−

2

HE.L P

−

3

4

A

V

HE.L P

−

4

5

A

V

HE.L P

−

5

6

A

V

HE.L P

−

6

7

A

V

HE.L P

−

7

A

V

HE.L P

−

0

A

V

HE.L P

−

9

8

1

Summary of Contents for NT 456 CC

Page 4: ...Notes ...

Page 14: ...OM 2243 Page 10 ...