.

A complete Parts List is available at www.MillerWelds.com

OM-232 384 Page 22

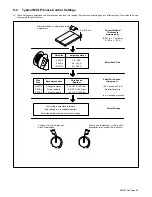

5-2.

Weld Parameter Chart

Input Line

Voltage*

Parameter

Chart Settings

Higher

e.g. 240

Volts AC

230 Volts AC

Lower

e.g. 218

Volts AC

Weld Will Be

Hotter

Lower Settings

Use Parameter

Chart

Weld Will Be

Colder

Raise Settings

*Line voltage can affect weld output, settings on this chart are starting values only. You may need to adjust

voltage and wire feed speed to optimize your settings.

Material

Suggested

ShieldingGases

AndFlowRate

Suggested

WireTypes

WireSizes

(Diameters)

0.023"(0.6mm)

0.030"(0.8mm)

0.035"(0.9mm)

0.023"(0.6mm)

0.030"(0.8mm)

0.035"(0.9mm)

STEEL

ER70s−6

100%CO

2

75%Ar/

25cfh(Ar/CO

producesless

spatter−better

overall

appearance)

2

2

Solid (or hard)

ER70s−6

Solid (or hard)

25 cfh

25 % CO

STAINLESS

STEEL

Aluminumwith

optional

Spoolmate

t

3035spoolgun.

Material

STEEL

Stainless

Steel

ER308,

ER308L

ER308LSi

Aluminum

4043ER

Suggested

WireTypes

Fluxcore

E71T−11

Tri−Mix,35cfh

(90%He/7.5%

Ar/2.5%CO)

2

100%Ar

Suggested

ShieldingGases

AndFlowRate

Noshielding

gas required

0.023"(0.6mm)

0.030"(0.8mm)

0.035"(0.9mm)

0.030"(0.8mm)

0.035"(0.9mm)

WireSizes

(Diameters)

0.030"(0.8mm)

0.035"(0.9mm)

0.045"(1.1mm)

25 cfh