12

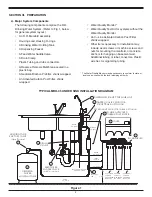

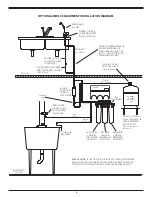

E. Position the Drinking Water Holding Tank

and Make the Final Hose Connections.

1. Check the tank precharge pressure. Make

sure it is between 5 to 7 psig. If not, use a

bicycle hand pump or other pump to bring the

pressure up to the 5 to 7 psig range.

2. Pull the cap/plug off the top of the tank where

the Tank Shut–Off should go. (Refer to Fig. 1)

3. Wrap Teflon tape three times around the ¼"

male outlet thread. Wrap in the direction of

the threads (clockwise when looking down

on the Holding Tank). The tape will act as a

thread sealant. Screw on the Holding Tank

Shut–Off Valve.

4. Locate the

3

/

8

" Yellow Tubing. Firmly press

one end into the Holding Tank Shut–Off Valve

and the other end into the tee. (Refer to Fig.

1) The fittings will grab the tubing and seal

it in place. Make sure the tubing is pressed

all the way in to create a pressure tight

connection.

F. Start Up

At time of start up and each time the filters are

changed the system should be sanitized (also

see Operation and Maintenance Sec. V, B.1–4).

1. Sanitizing the system. Use a drip pan to aid

clean–up.

NOTE:

The system should be sanitized

BEFORE installing the Sediment/Carbon

Prefilter, the Activated Carbon Post Filter or

the RO Membrane.

•Use a good quality unscented 5¼% liquid

chlorine household bleach.

•Open the Dispensing Faucet and open the

Holding Tank Shut–Off Valve (the handle

should be parallel with the valve body).

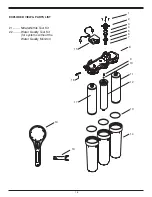

•Remove the plug on the underside of the

manifold labelled “SEDIMENT/CARBON”.

Pour one capful of bleach (this is

approximately 2 tsp. or 10 ml) into one of

the white Housings. Insert a Housing

O–ring into the Housing groove, (press

firmly in place). Engage and firmly tighten

the Housing hand tight only.

•Remove the plugs labelled “MEMBRANE”

and “ACTIVATED CARBON” from the

underside of the manifold. To each of the

remaining white Housings, add one capful

of bleach. Insert a Housing O–ring, engage

and firmly tighten the Housings hand tight

only.

•Slowly open the Feed Water Saddle Valve

(turning counter clockwise).

•As soon as the water begins to come out of

the Dispensing Faucet, close the Faucet.

•Let stand for 15 minutes.

NOTE:

During this time, check the system

carefully for leaks.

•At the end of 15 minutes, CLOSE the

Feed Water Saddle Valve and open the

Dispensing Faucet.

•Allow the Holding Tank to completely drain,

then remove the Sediment/Carbon Prefilter

Housing (the farthest of the three from

the In–Out ports), empty, and install the

Sediment/Carbon Prefilter. Firmly tighten

the Housing hand tight only.

•Remove the Activated Carbon Post Filter

Housing (the closest of the three to the

In–Out ports), empty, and install the

Activated Carbon Post Filter. Firmly tighten

the Housing hand tight only.

2. Installing the R.O. Membrane:

•Remove the R.O. Membrane Housing, (the

middle one), and empty.

•Insert the Membrane up into the manifold.

(The O–rings should be up toward the

manifold.) Check the Housing O–ring for

proper position in its groove, engage and

firmly tighten the Housing hand tight only.

3. Rinsing the system:

•Slowly open the Feed Water Saddle Valve

fully counter clockwise.

•The Holding Tank Valve should be open.

•Check the Air Gap Window on the

Dispensing Faucet to be sure that the drain

water is flowing. The R.O. System is now

making water.

•Do not open the Faucet for at least 8 hours.

•Do not use the first three full tanks of water.

CAUTION:

The R.O. Membrane is

shipped with a preservative in it. To ensure

proper rinsing of the R.O. Membrane, it is

important to wait at least 8 hours before

emptying each tank.

Summary of Contents for MRO-35

Page 15: ...15 NOTES ...