■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

4.5 Precautions While Lifting

DANGER

!

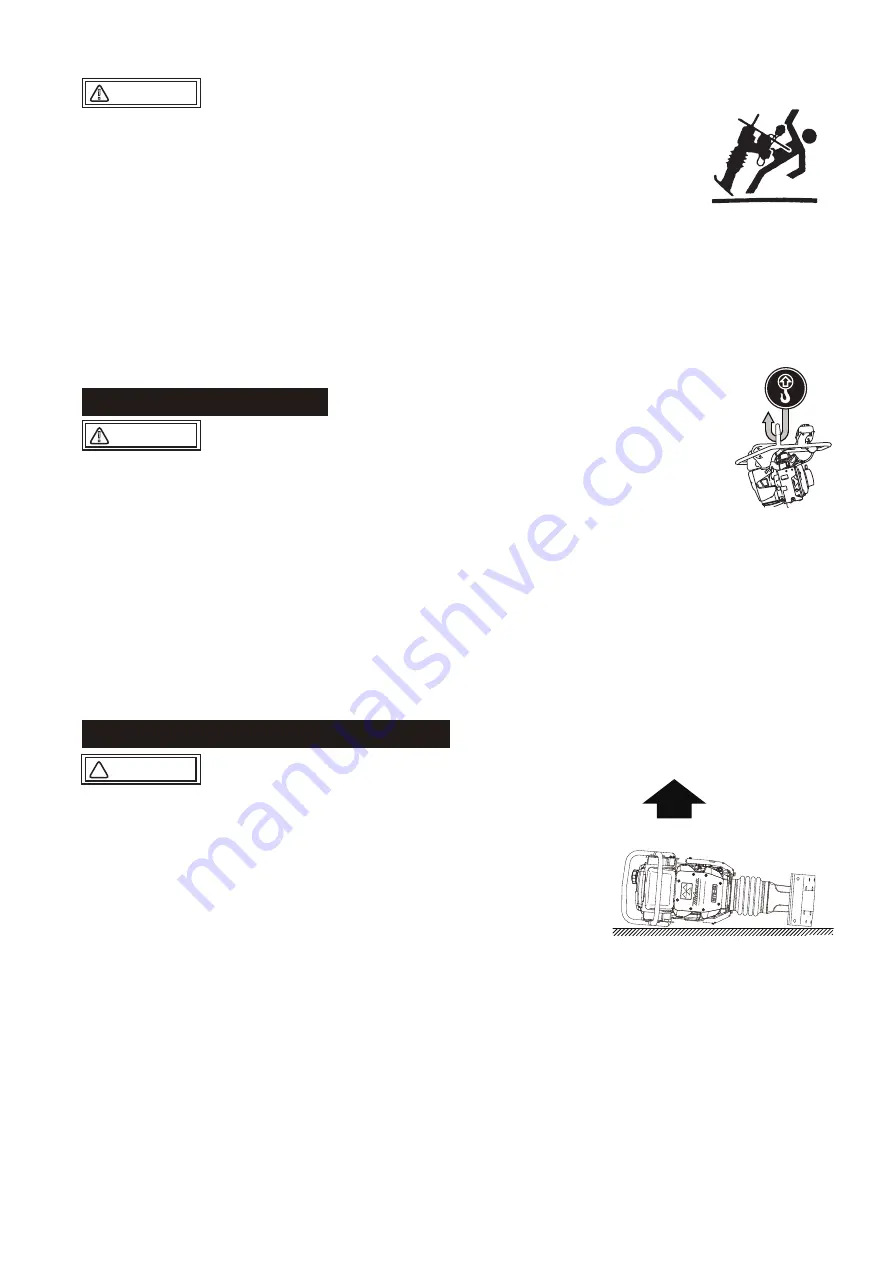

4.6 Transportation And Storage Precautions

DANGER

!

4

DANGER

!

Take the utmost care not to fall over the rammer during work, stored or

stopped. Tie down the rammer with cable (wire or rope) when stopped or

stored so that it cannot fall.

If the rammer falls over when children are nearby, they may have a seri-

ous accident.

If the foot of the rammer is worn, the rammer will be especially unstable.

If the foot of the rammer is severe worn, replace it with new one.

If the rammer falls over during work, it will move to forward due to kicking

motion of the foot while falling over. And if the ground is solid, the

rammer will move quickly so it is very dangerous. After ensuring that the

operator and people around are safe, move the throttle lever to the

engine stop position and make sure the rammer stops.

Take careful note of safe especially when working on the public road,

because a serious accident can occur easily.

Before lifting the machine, make sure that there is no damage to parts on

the machine (especially the shock absorber and the hook), loosening or

missing of the bolt, and the machine must be in a safe condition.

Stop the engine before lifting the machine.

Use adequate lifting cable (wire or rope) of sufficient strength for support to the machine.

Do not lift it higher than necessary for safety.

Do not use a damaged lifting cable.

Use one point lifting hook for lifting the machine and lift straight upwards. Do not use any

other points (such as the handle) for lifting.

Never lift or lower the machine rapidly with hydraulic excavator.

Never allow any person or animal to stand underneath the machine while lifting.

Be careful not to an accident when using any lifting equipment. Before using the lifting

equipment, make sure that there is no trouble or damage.

Stop the engine before transporting or storing the machine.

After the engine and main body have cooled down enough,

transport or store the machine.

Drain any fuel before transporting or storing the machine.

Maintain upright position of this rammer on a level floor

during transporting or storing. If it has to lay down the

rammer of necessity, drain the fuel, tighten the tank cap, and

then lay down it with muffler side down. After it lies down,

make sure that there are no oil or fuel leaks.

Tie down the rammer with cable (wire or rope) so that it

cannot move or fall over.

When lifting the rammer with the handle, be careful not to

pinch your fingers between the handle and main body.

When transporting the rammer, use MC-1A of Mikasa Carry

or similar product.

■

■

■

■

■

■