- 16 -

Close gas and

heard a sound

of fire

1.Insufficient gas pressure

in pipe

1.Contact the local

gas supply dept.

2.Not match nozzle aperture with

gas resources

2.Adjust

nozzle

diameter

3.Flow of connection pipe is

not enough

3.Increase

pipe’s

allowable flow

4.Damper opening degree is

too large

4.Adjust damper

Yellow flame

and

black

smoke

1.Use bottom gas

1.Change gas

2.Not match nozzle aperture with

gas resources

2.Adjust

nozzle

diameter

3.Not enough air to ignite

3.Increase damper

opening degree

4.In the peak of using gas,

sources of gas float heavy

4.Turn down valves

flow. Turn it up

after the peak

The problems mentioned above are only for reference. If any fault occurs, please

stop using, and contact technicians to check and repair. Safety first, turn off

the power and gas supply before maintenance.

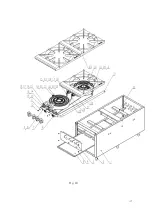

11. Spare Parts

The use of parts provided by other companies, our company has the right

not to provide warranty service;

Order replacement parts from authorized representatives and after-sale

service agency.

Provide the model number, serial number and description when you order

components.