11

7. Installation details

7.1 Wrench torque sheet for installation

Outside diameter

Torque

mm inch Kgf.m

Ф

9.52 3/8 4.2

Ф

16.0 5/8 6.6

7.2 Connecting the cables

The power cord of connect should be selected according to the following specifications sheet.

Grade

Unit 9K 12K

18K

24K

mm

2

1.5 1.5 2.5 2.5

7.3 Pipe length and the elevation

Capacity

Btu/h

Pipe size

Standard

length

(m)

Max.

Elevation

B (m)

Max.

Length

A (m)

Additional

refrigerant

(g/m)

Gas Liquid

24K 5/8’’

(

Ф

16.0) 3/8’’

(

Ф

9.52)

5 10 25 40

Caution:

Capacity is based on standard length and maximum allowance length is base of reliability.

Oil trap should be installed per 5-7 meters.

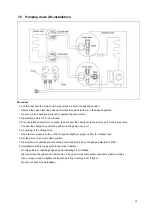

7.4 Air purging of the piping and indoor unit

Required tools:

Hexagonal wrench; adjustable wrench; torque wrenches, wrench to hold the joints and gas leak detector.

Note:

The air in the indoor unit and in the piping must be purged. If air remains in the refrigeration piping, it will affect the

compressor, reduce the cooling capacity, and could lead to a malfunction of unit.

Be sure, using a torque wrench to tighten the service port cap (after using the service port), so that it prevents the gas

Summary of Contents for MOF-24HDN1-QC2W

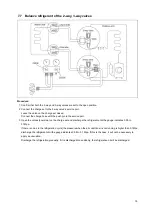

Page 10: ...8 5 Refrigerant cycle diagram...

Page 11: ...9 6 Wiring diagram 6 1 Indoor Unit...

Page 12: ...10 6 2 Outdoor Unit...