20301763

14

DVBL7 Series Gas Fireplace

VentInG InStaLLatIon InForMatIon

how to uSe the Vent Graph

The Vent Graph should be read in conjunction with the

following vent installation instructions to determine the re-

lationship between the vertical and horizontal dimensions

of the vent system.

1. Determine the height of the center of the horizontal

vent pipe exiting through the outer wall. Using this di-

mension on the Sidewall Vent Graph,

Figure 12

, locate

the point intersecting with the slanted graph line.

2. From the point of this intersection, draw a vertical line

to the bottom of the graph.

3. Select the indicated dimension, and position the fire-

place in accordance with same.

exaMpLe a:

If the vertical dimension from the floor of the unit is 11’ (3.4

m) the horizontal run to the face of the outer wall must not

exceed 14’ (4.3 m).

exaMpLe B:

If the vertical dimension from the floor of the unit is 7’ (2.1

m), the horizontal run to the face of the outer wall must not

exceed 7’ (2.1 m).

refer to

Page 18

for requirements for snorkels.

FP2337a

sidewall vent graph

2 4 6 8 10 12 14 16 18 20

40

38

36

34

32

30

28

26

24

22

20

18

16

14

12

10

8

6

4

2

.60 1.2 1.8

6.1

5.5

4.9

4.3

3.7

3.0

2.4

Meters

12.2

11.6

11.0

10.3

9.8

9.1

8.5

7.9

7.3

6.7

6.1

5.5

4.9

4.3

3.7

3.0

2.4

1.8

1.2

.60

X

Figure 12 -

Rear Wall Venting Graph

Horizontal dimension from the finished outside wall

to the center of the pipe on the fireplace

V

ertical Dimension From the Floor of Unit to the

Center of the Horizontal V

ent Pipe

eg: a

eg: B

t-LocK pIpeS

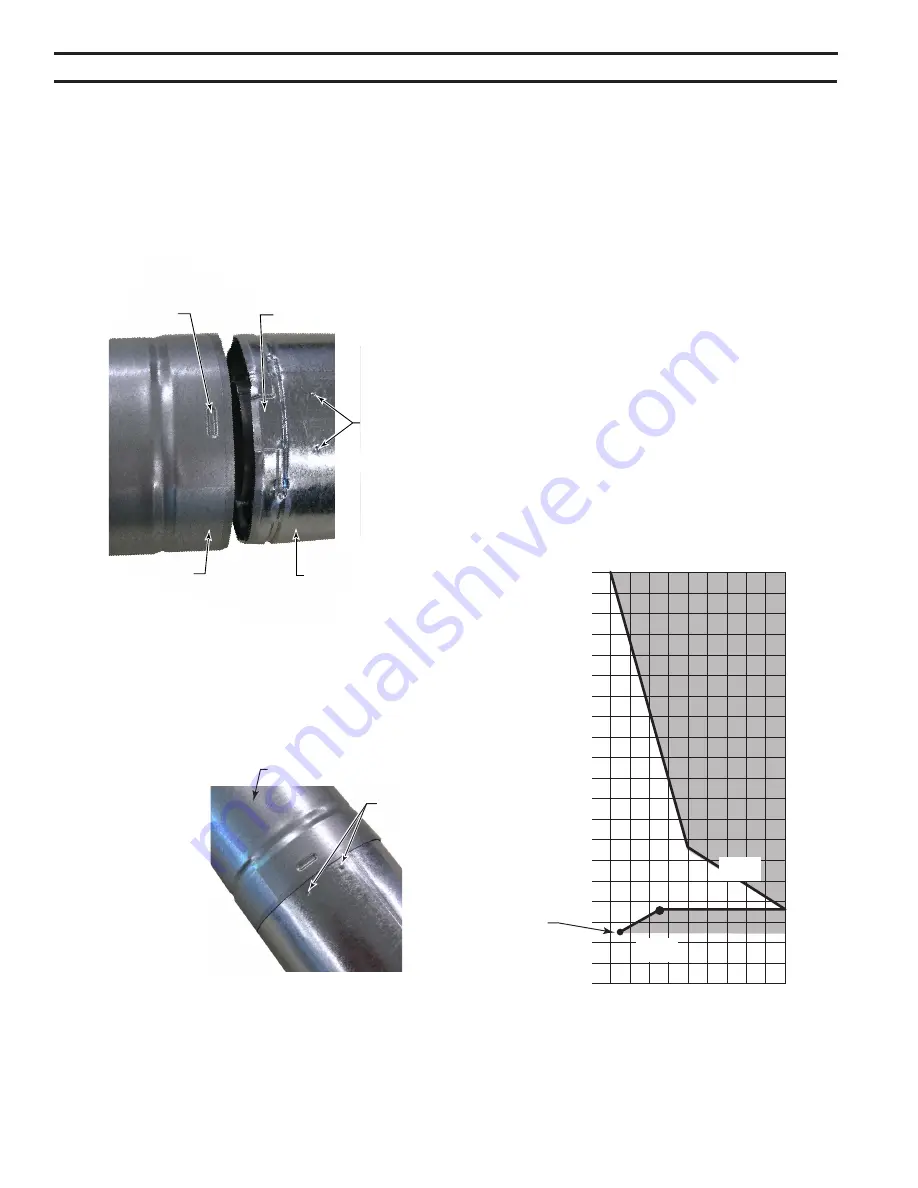

When using unitized T-Lock pipe it is not necessary to

use sealant on the joints. The only areas of the venting

system that need to be sealed with high temperature sili-

cone sealant are the sliding joints of any telescope vent

sections used in the system.

To join T-Lock pipes together, simply align both inner and

outer pipes with the next section. Align the internal beads

of the female end with the T-channels of the male end.

Figure 10

Insert male end until beads on the female end contact

bottom of T-channel on male end. Twist pipe until beads

stop at ends of T-channel.

IMportant: pipe can be twisted in either direction.

however, aLL pIpe SectIonS MuSt Be rotateD In

the SaMe DIrectIon.

Securing the joints with

sheet metal screws is

not required.

To make it easier to as-

semble the joints, we

suggest putting lubri-

cant (Vaseline or simi-

lar) on the male end of

the T-Lock pipe prior to

assembly.

To disassemble T-

Lock pipe, rotate pipe

sections until internal

beads on female end

are centered between the arrow indentations on male

end.

Figure 11.

Pipe sections will then easily separate by

pulling straight apart.

FP2741

T-lock undo

Arrow

Indentations

on Male End

Female End

FP2741

Figure 11 -

T-Lock Disassemble

X = 57" (1.5 m) minimum

(Floor to center of horizontal

pipe)

FP2740

T lock channels

Internal

Beads

T-Channel

Female End

Male End

FP2740

Figure 10 -

T-Lock Pipe Joints

Arrow

Indentations