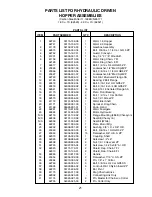

15

WARNING

1. As with all power equipment, safety is the number one concern.

2. Do not operate this equipment until you fully understand how it functions.

3. Before starting engine, be sure that no one is near the rear of the unit and that no one is inside the

unit!

4. Do not start the engine or engage the conveyor (which is interconnected to the spinner); until everyone

is clear from moving parts and flying material from the spinner.

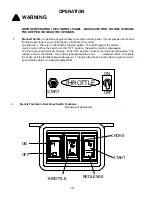

Electric Throttle Control Panel Switch Functions Cont.

A. ON/OFF

System power activated (ready to start). Spreader engine is not running.

Spreader conveyor is not engaged.

B. START (Engine only)

1.

Open fuel shut off valve on engine.

2.

On

On switch depressed.

3.

Choke

(cold engine ) Hold down for 5 seconds to move the throttle actuator to

the choke position.

Note: Choking a warm engine may not be necessary.

4.

Start

Hold down until engine starts.

4a.

On models with 6.5 HP at temperatures under minus 20

o

F (minus 29

o

C) it mat be

necessary to start the engine manually.

5.

Turtle

Deceases throttle speed - adjust as engine warms up. Will stop the choke function.

Rabbit

Increases throttle speed.

C. TO ENGAGE Spreader Conveyor

1.

Push CONVEYOR switch only after you are sure no one is in the hopper or near the spinner! This lights up

the red indicator light, if light does not light, take care to verify that the light is not malfunctioning.

D. TO CONTROL Conveyor Speed.

1.

Hold RABBIT to increase speed. NOTE: Do not hold switch in HI position after the desired RPM is achieved

or you will choke and/or stall the engine.

2.

Hold TURTLE to decrease speed.

E. TO DISENGAGE Spreader Conveyor.

1.

Tap START switch momentarily so that red indicator light goes out. Do not fully depress the START switch,

only half way is needed. Only the conveyor stops, the engine continues to run.

F. TO TURN ENGINE OFF (with or without conveyor running).

1.

Depress LO on throttle control to reduce setting to idle (this prevents engine flooding and hard starting).

2.

Push OFF position on the ON/OFF switch.

NOTE: OFF can be pushed at anytime during spreader operation to cut power to the unit . However, you

should normally use steps under F above.

(Once the off switch is depressed - the starting procedure must be followed for engine re-start.)

G. Do not attempt to start the engine with the conveyor engaged. (CONV switch light will be lit to indicating its'

being on.)

H. Close fuel shutoff valve on engine if unit is to be transported while not running.