18

KRBS 101 | Version 1.03

Disposal, recycling of used devices

11 Disposal, recycling of used devices

For environmental benefits it is necessary to ensure that

all components of the machine are only disposed of by

the provided and allowed means.

11.1 Decommissioning

Immediately decommission used machines in order to

avoid later misuse and endangering of the environment

or of persons.

- Dispose of all environmentally hazardous operating

materials of the used device.

- If required, disassemble the machine into easy-to-han

-

dle and usable components and parts.

- Supply the machine components and operating materi

-

als to the provided disposal routes.

11.2 Disposal of electrical devices

Electrical devices include numerous recyclable materials

as well as environmentally hazardous components.

These components must be disposed of separately and

professionally. In case of doubt, please contact your mu

-

nicipal waste management company.

For the recycling process, please request the assistance

of a specialized waste disposal centre if required.

11.3 Disposal of lubricants

The manufacturer of the lubricant makes the disposal in

-

structions for the used lubricants available. If applicable,

ask for the product-specific data sheets.

12 Spare parts

12.1 Ordering spare parts

The spare parts may be purchased with the authorised

dealer or directly with the manufacturer. Please find the

corresponding contact data in Chapter 1.2 Customer

service.

Indicate the following basic information for spare part or

-

ders:

- Type of device

- Serial number

- Quantity

- Designation

- Required mode of dispatch (mail, freight, sea, air,

express)

- Address of dispatch

Spare part orders which do not include the above indica

-

tions may not be taken into consideration. If the indica

-

tions regarding the mode of dispatch are missing, the

product is dispatched at the discretion of the supplier.

Example

The contact roller for the Combined pipe, section and

belt grinding machine KRBS 101 must be ordered. The

contact roller has the number 218 in the spare parts

drawing 2.

By ordering spare parts, send a copy of the spare parts

drawing (2) with the marked part (contact roller) and

marked positon number (218) to the dealer or spare

parts department and provide the following information:

- Type of device:

Combined pipe, section and belt

grinding machine KRBS-101

- Item number:

3921001

- Drawing number:

2

- Position nummer:

218

Item number of your device:

Combined pipe, section and belt grinding machine KRBS 101:

3921001

NOTE!

The manufacturer's warranty will become null and

void if non admitted spare parts are being used

DANGER!

Danger of injury by the use of

wrong spare parts!

Dangers may result for the user and damages as well

as malfunctions may be caused by using wrong or

damaged spare parts.

- Only use original spare parts of the manufacturer or

spare parts admitted by the manufacturer.

- Always contact the manufacturer in case of uncer

-

tainties.

Summary of Contents for KRBS 101

Page 1: ...KRBS 101 Instruction Manual KRBS 101 KRBS 101 Combined pipe section and belt grinding machine...

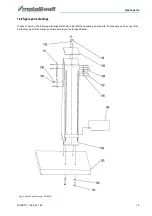

Page 20: ...20 KRBS 101 Version 1 03 Spare parts Fig 24 Spare Parts Drawing 2 KRBS 101...

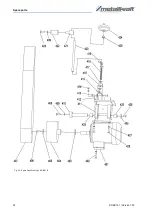

Page 21: ...Spare parts KRBS 101 Version 1 03 21 Fig 25 Spare Parts Drawing 3 KRBS 101...

Page 22: ...22 KRBS 101 Version 1 03 Spare parts Fig 26 Spare Parts Drawing 4 KRBS 101...

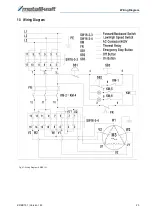

Page 23: ...Wiring Diagram KRBS 101 Version 1 03 23 13 Wiring Diagram Fig 27 Wiring Diagram KRBS 101...

Page 25: ...Notes KRBS 101 Version 1 03 25 15 Notes...

Page 26: ...www metallkraft de...