Transport, packaging, storage

HKS 320 | Version 1.04

9

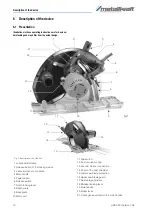

4.1 Type plate

Fig. 2: Type plate HKS 320

5 Transport, packaging, storage

5.1 Delivery and transport

Delivery

Check the metal-cutting circular saw for visible transport

damage upon delivery. In case of visible damage to the

metal-cutting circular saw, immediately notify the carrier

or your retailer.

Transport

Improper transport of individual devices, unsecured de-

vices stacked on top of each other or next to each other

in packed or already unpacked condition is accident-

prone and can cause damage or malfunctions for which

we do not grant any liability or guarantee.

Transport the scope of delivery secured against shifting

or tilting with a sufficiently dimensioned industrial truck

to the installation site.

General risks during internal transport

Devices may only be transported by authorized and

qualified persons. Act responsibly during transport and

always consider the consequences. Refrain from daring

and risky actions.

Gradients and descents (e.g. driveways, ramps and the

like) are particularly dangerous. If such passages are

unavoidable, special caution is required.

Before starting the transport check the transport route

for possible danger points, unevenness and disturban-

ces as well as for sufficient strength and load capacity.

Danger points, unevenness and disturbance points

must be inspected before transport. The removal of

danger spots, disturbances and unevenness at the time

of transport by other employees leads to considerable

dangers.

Careful planning of internal transport is therefore essen-

tial.

5.2 Packaging

All packaging materials and packing aids of the metal-

cutting circular saw are suitable for recycling and must

always be disposed of using material-based recycling

systems. Packaging materials made of cardboard must

be shredded and recycled as waste paper. The foils are

made of polyethylene (PE), padding is made of polysty-

rene (PS). Dispose of these substances at a recycling

centre or hand them over to a qualified waste disposal

company.

5.3 Storage

Store the metal circular saw thoroughly cleaned in a dry,

clean and frost-free environment. It must not be placed

in the same room with chemicals. During storage, the

metal circular saw should be covered with a plastic foil.

All bare metal surfaces must be provided with a suitable

rust protection.

CAUTION!

Injuries caused by parts falling over or off a forklift,

pallet truck or transport vehicle.

Only use means of transport that can carry the total

weight and are suitable for it.

CAUTION: DANGER OF TIPPING!

The device may be lifted unsecured by a maximum

of 2cm.

Employees must be outside the danger zone, the

reach of loads. Warn employees and, if necessary,

advise employees of the hazard.

NOTE!

Protect the metal circular saw from moisture.