4

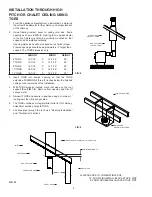

HIGH PITCH OR

CHALET CEILING

ROOF SUPPORT

(CAT. NO. TGRS)

(4) NAILS PER SIDE

TEMP GUARD

ADAPTOR INCLUDED

FIG. 8

FIG. 9

INSTALLATION THROUGH HIGH

PITCH OR CHALET CEILING USING

TGRS

1. From the appliance manufacturer’s instructions, determine

the correct flue diameter for the chimney and proper location

of the chimney.

2. Using framing lumber equal to ceiling joist size, frame

opening as shown in

FIG. 9

. Framing that is perpendicular

to the roof joists must also be vertically mounted so that

support can be installed vertically.

Opening dimensions will vary based on roof pitch (slope).

Framed openings should be approximately ¼” larger than

support. The TGRS dimensions are:

LENGTH

WIDTH

HEIGHT

6”TGRS

12-7/16”

X

12-7/16”

29”

7”TGRS

13-7/16”

X

13-7/16”

29”

8”TGRS

14-7/16”

X

14-7/16”

29”

10”TGRS

16-7/16”

X

16-7/16”

29”

12”TGRS

18-7/16”

X

18-7/16”

29”

3. Insert TGRS into framed opening so that the TGRS

extends a MINIMUM of three (3) inches below the finished

ceiling on the lower side of the installation.

4. With TGRS properly located, mark roof slope on the roof

support (See

FIG. 10.

), Remove from opening and trim off

excess metal.

5. Reinsert TGRS and secure in position using a minimum 1”

roofing nail, four (4) each per side.

6. The TGRS contains an integral starter collar for TG chimney.

Attach first section of pipe to TGRS.

7. Continue pipe through the roof. See “Flashing Installation”

and “Termination” sections.

FIG. 10

JOIST

SHEET ROCK

ROOF SUPPORT

CONNECTOR PIPE

MARK SLOPE AND TRIM OFF THIS PORTION

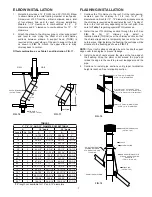

WALL STUDS

SHEET ROCK

3” MINIMUM LENGTH

18” FROM SINGLEWALL BLACK STOVE PIPE

6” FROM DOUBLEWALL BLACK STOVE PIPE

A

A=CLEARANCE TO COMBUSTIBLES OF: