IMO 10/19

4

IMO-215 EN

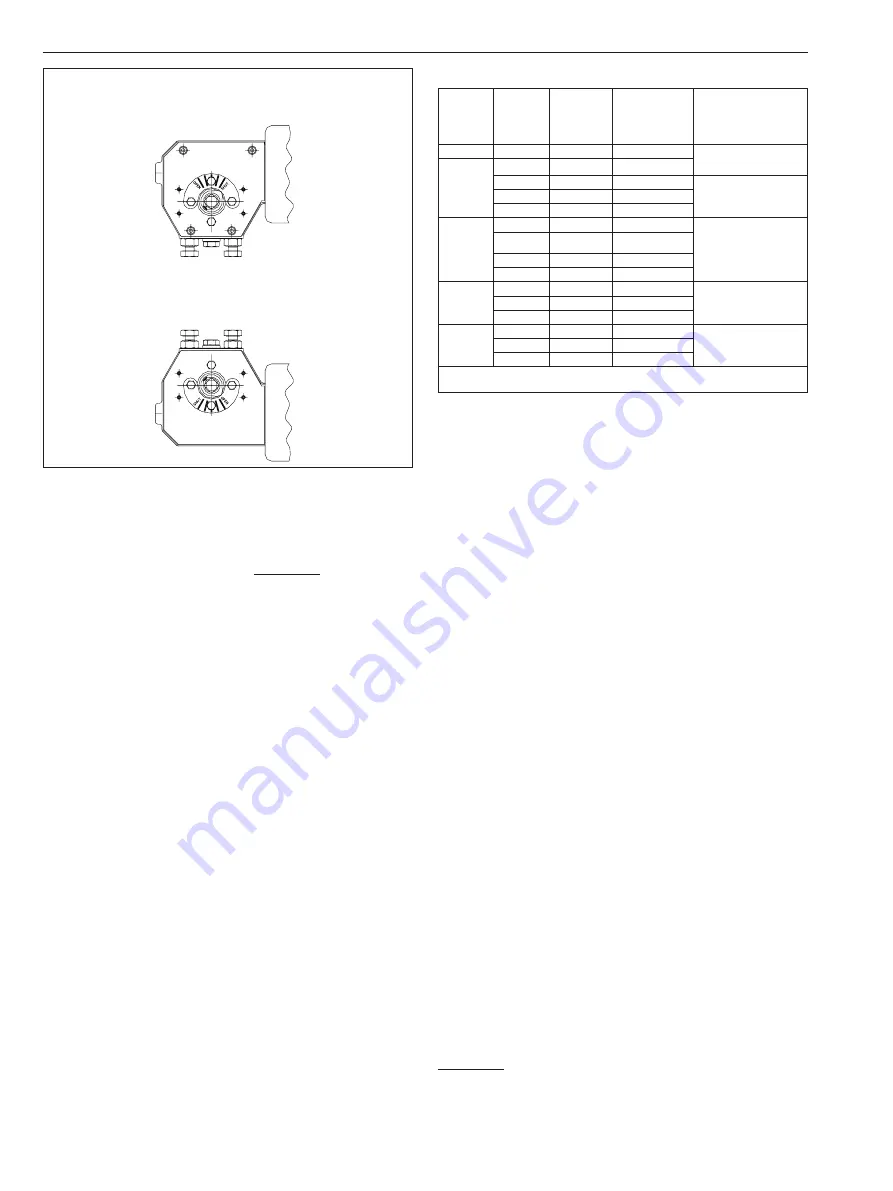

SPRING-TO-CLOSE

In this mode, the actuator will cycle clockwise

to close upon loss of pressure

SPRING-TO-OPEN

In this mode, the actuator will cycle counterclockwise

to open upon loss of pressure

Figure 2.

3. Mount the actuator to the valve following the directions

in the AMI (Actuator Mounting Instructions) or valve IMO.

4. Connect a regulated air supply to the 3/8" NPT fitting

in the diaphragm casing (15). CAUTION: The maximum

operating pressure is 100 psi (6.9 BAR).

5. Adjust the stop screws (19) by releasing the jam nut (23)

and turning. Stops can only be adjusted when driver

arm (3) is off the stop screws being adjusted. (Maximum

rotation adjustment ±5˚.) Be sure to retighten jam nut (23).

2.1

Operation

The operating pressure, output torque and drive type

is determined by the actuator designation. Maximum

operating pressure is 100 psi (6.9 BAR). (See Table 2)

Actuator designation example: QPX4C/K40 is a series QPX4

spring diaphragm actuator that has a 60 psi (4.1 BAR) spring,

an end of air pressure stroke output torque of 200 FT•LBS

(272 N•m) and uses a 40 mm female key to drive the valve.

Before operating make sure all tapped holes in the body

which are not being used are resealed with fasteners.

3.

MAINTENANCE

Although Metso’s

Jamesbury

actuators are designed to work

under severe conditions, proper preventative maintenance

can significantly help to prevent unplanned downtime and

in real terms reduce the total cost of ownership. Metso

recommends inspecting actuators at least every five (5)

years. The inspection and maintenance frequency depends

on the actual application and process condition.

Before working on a

Quadra-Powr

X actuator, note that all

fasteners except socket head shoulder screw (8) and hex

head cap screw (88, on QPX4 & QPX5) are metric.

Table 2

Actuator

Series

Spring

Version

Operating

Pressure

in psi

(BAR)

End of Spring

Stroke

Torque in

FT•LBS (N•m)

Drive Type

QPX1

C

60 (4.1)

25 (34)

K15 - 15 mm Keyed

M - 9/16” Square

QPX2

A**

20* (1.4)

11 (15)

B

40 (2.8)

38 (52)

K20 - 20 mm Keyed

M - 9/16” Square

C

60 (4.1)

57 (77)

D

80 (5.5)

74 (100)

QPX3

A

20* (1.4)

26 (35)

K35 - 35 mm Keyed

M - 3/4” Square

B

40 (2.8)

76 (103)

C

60 (4.1)

114 (155)

D

80 (5.5)

146 (198)

QPX4

B

40 (2.8)

153 (207)

K40 - 40 mm Keyed

M - 1” Square

C

60 (4.1)

229 (310)

D

80 (5.5)

294 (399)

QPX5

B

40 (2.8)

305 (414)

K40 - 40 mm Keyed

M - 1” Square

C

60 (4.1)

458 (621)

D

80 (5.5)

587 (796)

* For Direct Control Application

** QPX2A only available with QPX1 drive type options.

Under normal operating conditions the actuator requires

only periodic observation to ensure proper adjustment.

Standard replacement of “soft” parts in

Quadra-Powr

X

actuators consists of items numbered 6, 14, 31, 62 and 64.

See REPAIR KITS/SPARE PARTS Section.

1. When replacing the diaphragm use caution and be sure

the air supply is disconnected. Back off nuts (29) from

the hex head screws (27), holding the diaphragm casing

and spring housing together until the nuts are flush

with the hex head screw ends. Do not remove the nuts

completely from the hex head screws. If tension still

exists on the hex head screws, then the spring package

is not properly contained. Stop disassembly: retighten

nuts and return the actuator to the factory. If the spring

package proves to be intact remove the nuts (29) and

remove the hex head screws (27).

2. Lift off diaphragm casing (15). Remove hex head cap screw

(88) and retaining washer (89). Remove diaphragm (14).

3. Inspect the inside of both the diaphragm casing (15) and

the spring housing (32) for any rough spots or foreign

matter which may cause abrasion to the diaphragm.

4. Place the new diaphragm (14) on the diaphragm retainer

(10). Do not pinch or stretch the diaphragm. Attach

with washer (89) and cap screw (88). Tighten to value in

(Table 3) keeping spring housing (32) holes aligned with

diaphragm (14) holes. Place the diaphragm casing (15)

on the spring housing (32) and line up all the holes.

5. Insert hex head screws (27) in all holes. Do not force the

hex head screws through the diaphragm. Install nuts

(29) on screws and tighten uniformly using the standard

practice of tightening diametrically opposite bolts in

sequence with the torque requirements from (Table 3).

3.1

Disassembly

When disassembly of the actuator is required for

maintenance, remove the actuator to a clean well lit area.

Handling of the actuator is accomplished by using lifting

straps. See Section 1.2.

CAUTION: Disconnect any pneumatic or electrical supplies,

and vent any air pressure in the actuator before attempting

any disassembly.