Revision 2.2

Page 4 of 14

www.resourcedm.com

Mercury Switch User Guide

Warning

Please Note

The specifications of the product detailed on this

Set-Up Guide may change without notice. RDM

Ltd. shall not be liable for errors or for incidental

or consequential damages, directly and indirectly,

in connection with the furnishing, performance or

misuse of this product or document.

Ensure that all power is

switched off before

installing or maintaining

this product

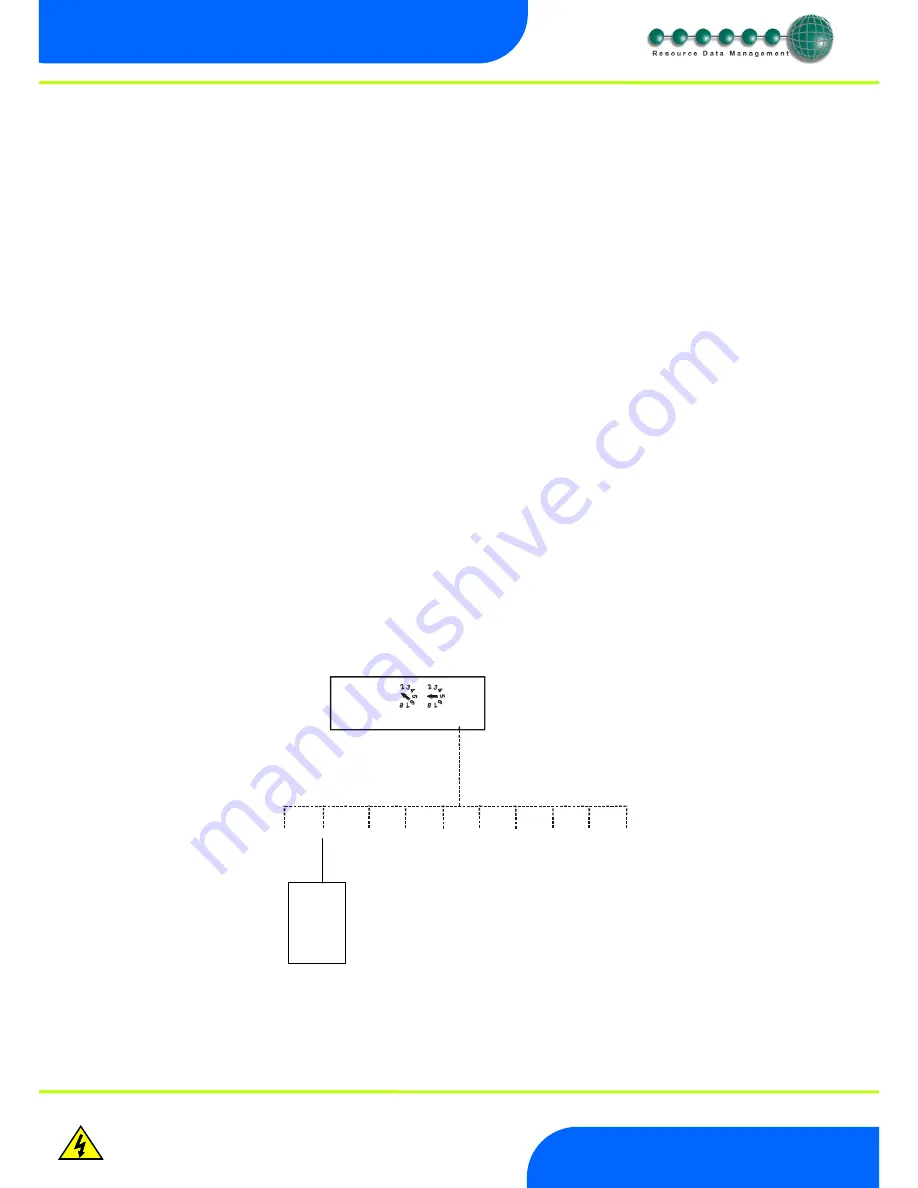

Connection to Mercury Controllers:

Using a standard CAT5 patch lead, connect the serial output of the RDM Controller to one of the RS232 ports of the Mercury Switch.

RS232 Lead Lengths

RS232 patch lead maximum length must not exceed 15 metres. (Ports 1 - 10)

The 3-character address that will be seen on the system front end is determined by the position of the two Network ID rotary switches

and the port the controller has been connected to, unless the connected controller has its own network ID rotary switches, in which case

the controller ID will override the switch settings.

Connection to other IP equipment

Use a standard CAT5 patch lead to connect other IP equipment to the Mercury Switch (such as a Futura IP module) into the 10/100 Base

T ports 1, 2 or 3.

Connection to another Mercury Hub/Switch or Other Ethernet Hub/switch

Use a standard CAT5 patch lead from any of the 3 10/100 Base T ports into any of the 3 10/100 Base T ports on the upstream Mercury

Switch. The 3 10/100 Base T ports are all self configuring.

Connection to a Data Manager/Director

Use a standard CAT5 patch lead and connect the Data Manager or Data Director to one of the 3 10 Base T ports.

10/100 Base T connectors

The three 10/100

Base T connectors have 2 LED’s adjacent to them: The green LED; when static, indicates that the connection to the

device is good, the green LED then flickers when data is being transmitted.

When the amber LED is permanently on it indicates that the connection is full duplex and if there is an error or fault on that channel the

LED flickers.

Network ID

The 3-character network ID is made up from the positions of the 2 rotary switches and the RS232 connector number. We recommend

that the 2 rotary switches are set to the Bay number and that the case sections are plugged into their corresponding RS232 port

numbers.

E.g. Bay 10 case 2:

The 2 rotary switches set to "1" and "0", controller plugged into port 2. The ID then is seen as "102" at the system front end.

Note that case number 10 would plug into RS232 port 0 (right most port) and come through as "100".

ID for equipment with rotary switches.

For RDM products that use the 3 rotary switches for the network ID (such as Mercury Power tray), the ID will follow what is set on the

controller local switches and

NOT

the port position on the Switch.

1

9

0

1

9

0

NETWORK ID

1

2

3

Vdc

1 2 3 4 5 6 7 8 9 0

Controller

at position 2