MCR

P

ROSMOKE

FS

O

PERATION AND

M

AINTENANCE

M

ANUAL

Page 3 of 20

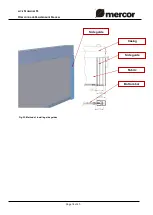

1.

Suspension bracket

2.

Casing

3.

Smoke-tight fabric

4.

Bottom bar

5.

Masking element holder

6.

Masking element

The roller is mounted inside the casing by means of a bearing unit with a pivot on the

one side and on the motor spindle on the other. In specific cases, a second drive system can

be applied instead of a bearing unit.

The drive system mounted in the roller consists of a 230 V~ motor, a 24 V~ brake

keeping the fabric rolled up, and an additional brake limiting the rate of dropping down.

The smoke-tight fabric has a bottom bar ensuring correct rolling out and rolling up and

minimising the risk of bending and lifting the fabric when affected by the pressure of fire

gases. The bottom bar may be optionally equipped with a masking element

(fig. 5)

.

The masking element is an 80 mm wide aluminium profile painted to order in any RAL

colour.

The smoke-tight fabric used in

mcr PROSMOKE FS

curtains is not trimmed at the

edges. Slight edge fraying is natural and does not affect the operation and product quality.

The curtain casing houses the MECU XL control system ensuring correct operation of

the curtain.

Single curtains are up to 6 m long. If longer curtains are needed, a proper number of

shorter curtains are put together to form a unit of the desired length.

The curtain may be optionally equipped with gap-reducing side guides.

Fig. 1. mcr PROSMOKE FS rolling smoke curtain

– design

Curtain

casing