CORRECT GAS PRESSURE AND PROPER GAS SUPPLY LINE SIZING ARE IMPERATIVE TO THE SUCCESSFUL PERFORMANCE OF YOUR

MENDOTA GAS STOVE. BE SURE THE GAS SUPPLIER OR PLUMBER CAREFULLY CHECKS FOR CORRECT GAS PRESSURE AND GAS LINE

SIZING WHEN INSTALLING THE STOVE.

IT IS CRITICAL TO CAREFULLY CHECK FOR GAS LEAKS WHEN HOOKING UP THE STOVE -- CHECK WITH SOAP & WATER SOLUTION.

BE SURE TO INSTALL FLEX GAS LINE WITH BRASS-TO-BRASS FITTINGS TO PREVENT GAS LEAKS AT CONNECTIONS.

GAS SUPPLY PIPING MUST INCLUDE A DRIP LEG TO ELIMINATE THE POSSIBILITY OF CONTAMINANTS ENTERING THE GAS TRAIN.

ADHERE STRICTLY TO LOCAL AND NATIONAL CODES.

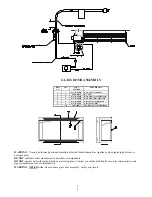

GAS SUPPLY LINE SIZING

The Mendota Gas Stove comes equipped with a 3/8" N.P.T. (1.Ocm) inlet nipple on the back of the pedestal.

The proper gas line diameter must be selected to run from the supply regulator to the Stove. Refer to the following

table for proper gas pipe diameters.

Table 1: Gas Supply Line Sizing

PIPE LENGTH

(FEET)

SCHEDULE 40 PIPE

INSIDE DIA.

TUBING, TYPE L

OUTSIDE DIA.

NAT.

L.P.

NAT.

L.P.

0-10

1/2" (1.3cm)

3/8" (1.0cm)

1/2" (1.3cm)

3/8" (1.0cm)

10-40

1/2" (1.3cm)

1/2" (1.3cm)

5/8" (1.6cm)

1/2" (1.3cm)

40-100

1/2" (1.3cm)

1/2" (1.3cm)

3/4" (2.0cm)

1/2" (1.3cm)

100-150

3/4" (2.0cm)

1/2" (1.3cm)

7/8" (2.3cm)

5/8" (1.6cm)

150-200

3/4" (2.0cm)

1/2" (1.3cm)

7/8" (2.3cm)

3/4" (2.0cm)

NOTE:

Some areas allow copper tubing or galvanized pipe - check with local approval agencies and codes. NEVER use plastic pipe.

GAS PRESSURE CHECKING REQUIREMENTS

Brass fittings for checking gas pressure are located on main gas valve. A qualified installer should use then fittings

for setting the correct gas pressure during initial installation. (See “INLET GAS SUPPLY PRESSURE”, page 17).

The Appliance and its individual shutoff valve must be disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of 1/2 PSIG (3.5 kPA).

The appliance must be isolated from the gas supply piping system by closing its individual manual shutoff valve

during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 PSIG (3.5 kPa).

NOTE:

DO NOT DAMAGE OR KINK THE FLEX CONNECTOR

CHECK FOR GAS LEAKS WITH SOAP AND WATER SOLUTION.

NOTE:

3/8" FLEX OR RIGID PIPING MAY BE USED TO

CONNECT GAS SUPPLY TO UNIT.

NOTE:

BE SURE TO INSTALL FLEX GAS HOSE WITH BRASS-TO-BRASS

FITTINGS TO PREVENT LEAKS AT CONNECTION

.

FIGURE 6: Piping Detail

1

6

Summary of Contents for MEDALLION

Page 21: ...Log Fire View Figure 9 Log Module 2 0...

Page 33: ...NOTES NOTES 3 2...